We started our day with our weekly ham radio breakfast in South Lyon. As we were leaving breakfast I called Chuck to see if he was at his shop. He wasn’t but said he could be there between 11 and 11:30 AM. We drove home, loaded up my car with the accumulated recyclables, headed over to Recycle Livingston, and then headed to Chuck’s shop in Novi. We arrived before he did and let ourselves in. I got his Dremel tool kit and pistol style soldering gun and we chatted for a while. He had a noon appointment with someone at a commercial building he owns in Livonia, and we had a long list of project tasks to take care of, so it was a shorter chat than usual. We stopped at the Lowe’s in New Hudson and bought a can of garage door spray lube and then headed home, stopping for fuel at the Brighton Shell station on Grand River Avenue at I-96.

At our ham radio breakfast Linda had rye toast and I had an English muffin for breakfast (our usual meals) so we were hungry by the time we got home. We had roll up sandwiches of hummus, Vidalia onions, and greens with a drizzle of olive in a whole wheat pita. Very tasty. We then got to work installing the wall-mounted track for the ZioTek monitor mounting system I bought from CyberGuys.

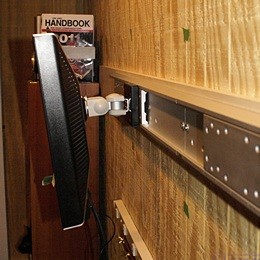

The north wall of the ham shack. Critical points for the mounting of the ZioTek track system are marked with green tape.

Conceptually the installation was simple but it took all afternoon. There is a kind of alcove at the north end of my office that serves as our amateur radio (ham) shack. The purpose of the ZioTek system is to support up to four monitors on the north wall above the two desks located there so that they are not attached to the desks or using up any of the desktop real estate. The walls in the office are 7/16ths inch thick T-111 exterior plywood with 1/2″ grooves on 4″ centers running the length of the plywood sheets. The sheets are installed vertically so the groves run vertically giving the appearance of vertically installed 4″ wide rough sawn boards. We finished the photo studio/office at the old house with this material so we knew we liked the way it looks. Being plywood it has once major advantage and one major disadvantage compared to drywall; you can screw relatively heavy things to it, but holes are essentially impossible to repair. What that meant for us was that we only had one chance to get the track in the correct location.

In this case “correct” meant: at the right height and horizontal location to be able to position the monitors exactly where we wanted them while making sure the track was level. To accomplish this I bought a 1″x6″-8′ poplar board to use as a mounting plate for the two track sections. (All of the trim in the ham shack/office is poplar.) We used pieces of tape to mark the locations of the corners of the three monitors on the wall and marked the centers of the VESA 100×100 mounting plates. When we knew where the horizontal centerline of the tracks needed to be we determined the horizontal location of the tracks relative to the right end of the poplar board, which would be installed flush to the vertical trim in the northeast corner of the alcove.

The ZioTek tracks will mount to the horizontal poplar board which will be mounted to the wall at the studs.

We set the poplar board in the utility hallway and positioned the two tracks on it. I butted the tracks together and slid one of the mounting plates so it saddled both tracks and kept them aligned. The tracks are 4.5″ wide and the board was 5.5″ wide so I very carefully positioned the tracks for a 1/2″ reveal along both edges. I then marked the eight mounting holes (four in each track) and removed the tracks. Using a brad point wood bit that was slightly smaller than the central shaft of a #14 wood screw I drilled holes that were as carefully centered as I could make them.

We held the board in position against the wall and used a 1.5″ #6 finishing nail through the right mounting hole to hold that end of the board. We then used a 4-foot level on the top edge of the board and secured the left end with a second nail through one of the mounting holes. We positioned the chair where it will be when in use and made sure we liked the height of the board. It looked and felt right so we proceeded to secure it to the wall.

The ZioTek tracks mounted to the poplar board mounted to the wall. Linda is vacuuming up sawdust from drilling.

Using a small carpenter’s square I marked locations for mounting screws one inch in from each edge of the board in vertical alignment with the small heads of the nails that secure the T-111 to the studs. The 8-foot long board spanned six studs so I had 12 holes to drill. I used a standard drill bit that was slightly smaller than the shaft of a #14 wood screw and drilled through the poplar board, through the T-111, and into the studs. I used a countersink bit to create recessed pockets for the flathead wood screws. We then secured the board using 3″ long #14 flathead wood screws. We applied a little soap to the screw threads to help them go in.

I pulled the two small nails out of the track mounting holes. Using the same drill bit I finished drilling out the mounting holes all the way through the T-111. We positioned and partially installed one track using 2″ long #14 flathead wood screws in the two end mounting holes. We then did the same thing with the other track. I slid one of the mounts so that half of it was in each track and partially installed the remaining four screws. I gently snugged up all eight screws, checking the track alignment as I went, and then torqued them down. The heads stick up above the inside surface of the track but the shuttle mounts are raised on the underside so they slide right over the screw heads without interference.

With the track mounted to the wall we turned our attention to installing the monitor mounting arms and monitors. We used one of the long arms on the left, the short arm in the center, and the medium arm on the right. The other long arm will eventually end up on the far right or get swapped for the medium arm, but for now I only wanted to mount three monitors. We installed the nice Dell monitor that goes with my older Dell Precision laptop in the center and installed the two ASUS monitors to either side of it.

By the time we got the third monitor mounted the office was in more disarray than usual and we did not have time to clean up tools and put things back in order. Linda did manage, however, to run the vacuum cleaner and get most of the sawdust and wood chips sucked up. Our son had called during the afternoon with a last minute request for babysitting services from Linda and I decided to go too.

We left at 6 PM for Ann Arbor and stopped at the Whole Foods Market to pick up a few things for dinner. We got two different vegan sushi rolls, a cold couscous salad, and some organic black grapes. When we arrived at Brendan and Shawna’s house a little before 7 PM Madeline was surprised and excited to see us. Brendan and Shawna left around 7:15 PM for an engagement party and Madeline was fine with the whole thing. She was still eating her blueberries and strawberries and then wanted Linda to read several books to her. We went upstairs to see how her crib had been converted to a toddler bed, allowing her to get up during the night to use the bathroom. Such a big girl. But not too big for pajamas that featured fairies.

After another couple of stories Madeline went to bed without a fuss. We then had dinner. The California rolls were OK but the couscous salad was outstanding and the grapes were very good. We sat on the couch using our iPads but I could not stay awake so I laid down and drifted off to sleep. I was awakened about 90 minutes later by the return of Madeline’s parents. Linda gathered up our leftover food and the roses the kids had gotten her as a “thank you” for babysitting on such short notice which gave me time to fully wake up. We were on our way by 10:30 PM and back home shortly after 11.