2016/04/06 (W) Near Disaster

We were up by 7 AM, anticipating our departure from Jetty Park and the Cape Canaveral / Cocoa Beach area of Florida. Around 9:30 AM we started straightening up the interior of our motorcoach. At 10:15 I moved the car over by the office and walked back to our site. Around 10:30 I disconnected the shorepower cord and stored it for travel. With the chassis batteries connected, and the engine compartment accessory air supply open, the engine started right up. After the chassis aired up I raised the tag axle and Linda served as spotter while I eased out of site #357. I thought I might need to back up to get clear of vehicles and trees but I was able to exit the site in one smooth forward motion. Linda got onboard and we drove clockwise around Red Knot Circle and over to the dump station by the office. There is a large paved area around the dump station with room to temporarily park the bus, without blocking any of the vehicles parked there, while we connected the car for towing. We checked the lights, which were OK, and Linda got onboard. We pulled out of the campground just after 11 AM and once I cleared the turn out of the campground exit I lowered the tag axle. I felt a sudden jerk but thought the transmission had shifted.

We headed west on George J. King Blvd. and merged onto FL-A1A westbound. FL-A1A quickly crossed the Banana River, leaving Cape Canaveral for Merritt Island. We eventually crossed the Indian River and were back on the mainland. Somewhere along the way FL-A1A became FL-528 which eventually became FL-528 Toll Road. Linda was keeping tabs on the temperatures and pressures of all the wheels/tires. The driver side tag seemed to be running consistent with the others and we settled in for our trip.

FL-528 traverses a large swath of undeveloped land with lots of water and birds. Traffic was light and the driving was easy so it came as quite a jolt when we got a high temperature alarm on the driver side tag axle tire sensor. The temperature was in the 160’s and climbing and I started looking for a safe place to pull off the road. Before I could do that I checked the driver side rear view mirror, and saw smoke coming from the tag axle wheel well. NOT GOOD! I pulled off at an entrance ramp to get farther away from the traffic lanes. I told Linda to get our cats into their carriers and grab our computers from the bed in case we had to abandon ship. While she did that I grabbed the fire extinguisher from behind the driver’s seat and ran back to the smoking tag axle. I discharged the extinguisher through the small holes in the wheel in an attempt to cool off the disc brake caliper and rotor. I got the wheel to quit smoking and went back inside to get the other fire extinguisher, just in case.

I left the engine running and started trying to figure out what to do. My first call was to the Prevost Service Center in Jacksonville, Florida. They could not help me directly, and their mobile service guy was off today, but the service manager gave me the name of someone to call in the Orlando area. Long-story-short, I ended up getting passed off to a whole string of people, none of whom could help me but each of whom tried to connect me to someone who could. No one could provide assistance in-situ and most places would not be able to help us for 1 to 2 weeks, if at all.

I talked to a guy in Cocoa, about 20 miles back the wrong way, who sounded like he could help in a week if we could get the bus there. I eventually talked to our mobile mechanic, Joe Cannarozzi, who was in Michigan working on a coach near Lansing about 30 miles from our house. I also called the Prevost Action Service System (PASS). The Jacksonville service manager was not willing to tell me it was OK to lift the tag axle and drive on six tires but the P.A.S.S. technician thought it would OK as long as I did not drive too far and kept my speed down. I eventually talked to Barry at JOSAM in Orlando, who could not help us directly but seemed genuinely concerned about our situation. Barry ultimately put me in touch with John at Action Mobile Service on the south side of Orlando. Both business were located near the intersection of the FL-528 Toll Road and FL-91 (Florida’s Turnpike). That intersection was about 15 miles from where we were sitting on the side of the road. The consensus opinion was that I should be able to complete the relatively short trip of 15 miles by lifting the tag axle and limiting my speed. By the time I pulled back into the flow of traffic we had been on the side of the road for two hours and were more than a little bit rattled and frustrated.

Limiting my speed on a limited access highway posted at 70 MPH was not without its own risks, but it was (apparently) our only alternative unless we wanted to be put on a “low boy” and towed. The sooner we got off FL-528 and into someone’s service yard the better. Traffic was now thicker as it was 1:30 PM but I finally had an opening that was long enough to allow me to get up to 45 MPH without cutting someone off and give other vehicles plenty of time and distance to move over and go around me. I kept my speed at 45 to 50 MPH, except where posted lower in a construction zone, of course, and kept my emergency flashers on the whole way.

We exited FL-528 at Exit 4. When I started driving I was headed for JOSAM and Barry had given me a ‘heads up’ about how to navigate Exit 4 as this exit serves a dual purpose. Staying to the right it immediately becomes an entrance ramp to FL-91 (Florida’s Turnpike) whereas staying left and going straight to the stop sign gets you to a side street that leads to FL-441 / Orange Blossom Trail to the right or to JOSAM to the left. We were nearing Exit 4 when Barry called back and told us to go to Action Mobile Service. Exit 4 was also the correct exit for Action Mobile but in the opposite direction from JOSAM. It was at this point that we had a bit of confusion.

We were both already pretty frazzled by the events of the last few hours and the last minute change in directions did not make things better, especially with Linda handling the phone call and unable to hear well. We had JOSAM’s address programmed into the Rand-McNally TripMaker RVND 7710 GPS, but that was no longer our destination. Linda tried to enter the address of Action Mobile Service into the unit but it had become non-responsive. I checked the power adapter and saw that the light was out so I knew the unit was not getting 12 VDC power and the battery had probably run down. The adapter often works loose so I plugged it back in but it did not restore the power. The two bottom outlets share a circuit and the two upper outlets share a different circuit so I plugged the adapter into one of the upper outlets. I quickly determined that all four of the 12 VDC accessory outlets appeared to be dead and told Linda to stop trying to use the GPS. She put the address in her phone instead but was having trouble with that as well and was slightly disoriented by this point.

I knew we had turn right at the stop sign because Action Mobile was “in the opposite direction from JOSAM.” I also knew I needed to get onto Orange Blossom Trail, but was unclear as to just where that was or which way we needed to turn when I found it. As it turned out I could see a street sign that indicated OBT was the cross street at the traffic signal immediately after we turned right at the stop sign. We were where we needed to be, but now which way to go? On a hunch, when the light turned green, I turned right and headed south. Linda got oriented relative to the GPS/mapping information on her phone and eventually confirmed that we were closing the distance between our current location and destination and thus going in the correct direction on the correct road. I turned left onto the Central Florida Parkway and then a short distance later turned right onto Satellite Blvd. Action Mobile was the second business on the right but I pulled up along the curb, making sure I did block any driveways, and walked in to confirm that we were in the right place and find out where they wanted me to put the bus.

We were met by the Service Manager, John Provo, who pointed me to an open area where I could back the bus in and be out of the way. We unhooked the car and Linda drove it into the yard and parked it near where the bus would end up. I then swung the bus out into the oncoming traffic lane and made a hard right turn through the gate and into the yard. (The tag axle was already up, of course.) I pulled forward and then backed in towards the passenger side with Linda spotting for me. I put the tag axle down so the drive axle would not have to support the entire weight of the rear end and checked for level. We were level enough for comfort so I did not bother with leveling. Once we were parked I went in to talk to John (the service manager, the owner’s name is also John). He and I looked at the driver side tag wheel/tire and I described what had happened. Other than the yellow powder from the fire extinguisher there was no visible evidence of what had transpired.

Owner John Douglass was outside talking to someone and Linda ended up talking to him. In the course of their conversation she found out that his parents owned a house on Runnymeade in the same subdivision where we lived for 35 years. Not only that, they were there when we were, and John lived with them for a while after trade school (diesel mechanics). He eventually bought the house from them, again, all while we were there but we did not recall ever meeting. It really is a small world, after all!

John D. (the owner) introduced us to Bill (the mechanic) who would be handling our repair first thing tomorrow morning. There wasn’t much else to do at that point except to get comfortable, have a late lunch snack, and check in with “Smitty” (John Smith) at Williston Crossings, Pat/Vickie, Butch, and Chuck while Linda updated our children on the status of our situation.

The last employees left around 5 PM and closed/chained the gate. We had the code for the lock but the lock was on the outside of the fence. An employee returned around 6 PM so when he left I went out and put the lock on the inside. It did not occur to me at the time that employees might have to get in at all hours for emergency road service calls, but I was willing to get up and unlock at whatever hour if needed.

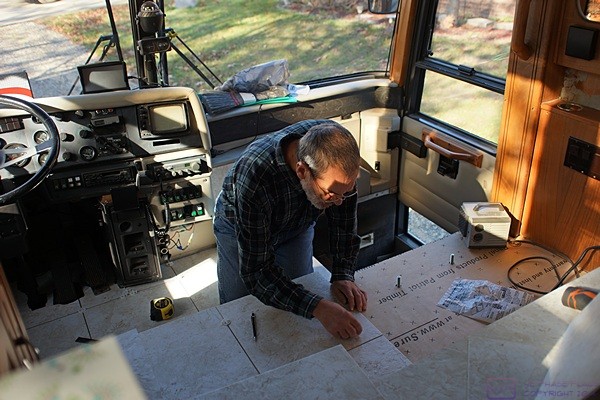

It would be a while until our evening TV programs came on, and we still had plenty of daylight, so I got out my multi-meter to try and diagnose what had happened with the power supply to the four 12 VDC accessory outlets I wired up for powering portable accessories in the cockpit. The 12 VDC distribution/fuse panel seemed like the obvious place to start.

The 12 VDC distribution/fuse panel is above the entry stairs from the cockpit landing up to the main floor. It’s an enclosure that is installed against the ceiling and is about 10″ high. It is in-between the TV box (DS) and the front A-C box (PS) and is about 28″ wide. It has a door that is 7″ tall by 24″ wide and hinged at the top, opening out from the bottom. When the door is open the actual opening is, of course, a bit smaller. The hinges on the door do not hold the door open against the ceiling, so one of the challenges working in this space is keeping the door up and out of the way. When working alone I usually prop it open but with Linda helping me she was able to hold it open with one hand and hold the multi-meter with the other hand while I handled the probes. The other challenge is that it is above the stairs and just high enough that I cannot reach it easily without standing on a stool, which is what I did while Linda stood with her right foot on the navigator seat and her left foot on the main floor. It was probably a strange sight if anyone noticed.

Each circuit has have a number tag on the wire where it connects to the fuse block terminal. We are fortunate that one of the pieces of documentation we got with the coach lists all of these circuits in numerical order with a description of what it feeds. I recalled (vaguely?) that I had disabled and/removed some devices a while ago and repurposed the circuits to supply power to the auxiliary outlets. I found the circuit numbers and checked those and they did not have power. I traced the problem back to a relay that did not seem to be operating correctly.

I carry spare relays and was going to replace it but discovered, after great difficulty removing the relay from its socket, that my spare relays were slightly different (4-pin instead of 5-pin). I spent some time considering whether I could use a 4-pin relay, or perhaps just install a jumper wire to bypass it, when I realized that there were a few duplicate wire numbers, and that those duplicates were the very numbers with which I was working. I checked for 12 VDC on those duplicate circuits and guess what? No voltage there either. I pulled one of the automotive style blade fuses and it was open.

I got the parts box with the spare fuses from the car and found a correct replacement. I checked the other two fuses and they were also open. They were very small, 2 and 3 A respectively, and I replaced them with 5 A fuses. After reconnecting a wire (that I had already forgotten I disconnected at the beginning of this process) we finally had power restored to all four outlets, which, as I mentioned earlier, get their power from two different circuits, one for the upper pair and a different one for the lower pair.

We spent the night in Action Mobile’s yard. Located in a light industrial area just off a major commercial thoroughfare, it was certainly not an RV park, but it was fenced, with barbed wire on top, had a locked gate (for which we had the code), and lots of security cameras. Satellite Blvd. was surprisingly busy for a side street, with lots of trucks of all sizes and some hot rodders with booming car audio systems. There was a large food processing plant directly across the street that was brightly illuminated and obviously in production 24 hours a day as there were lots of cars/trucks that left around 7 PM and a larger number that showed up at the same time and parked all along the building.

We had been running on inverters all day and I wanted to make sure the batteries were close to fully charged before we went to bed so I turned on the genset around 7 PM while we watched TV and tried to relax. I used TVFool.com to locate OTA TV transmitter antennas. Given that we were on the south edge of Orlando the towers were, not surprisingly, in all directions. Most of the strongest stations, however, were lined up to our northeast so I pointed the front TV antenna in that direction. We were able to pick up one of the PBS affiliates and watched a fascinating program of the Vikings; their journeys and reach, and the use of satellite imaging technology to identify possible archeological sites in what is now the Canadian Maritimes.

We had to be up at 5 AM so we were dressed and ready to go at 6 AM which is the time I was told Bill would be arriving. I set two alarms and we went to bed around 11 PM.

2016/04/07 (R) Crisis Averted

It rained overnight and continued, off and on, this morning. We were up around 5:15 AM, got dressed, and had bagels and orange juice for breakfast but I did not make any coffee. Bill (our mechanic) was the first to show up at 6:45 AM. Since the lock was on the inside of the gate I walked over to make sure he could get it open. Just before 7 AM an ALSCO truck pulled in. There were two other ALSCO trucks in service bays and the driver walked over there, came back a short time later, and then drove away. Bill unlocked the office and then settled in at the outside picnic table. I realized pretty quickly that nothing was going to happen with our bus until John P. (Service Manager) showed up, but that was OK. It was a great comfort to be off the road in a safe place where we could sit for quite a while if needed and to know that there was a guy who had the skills and resources to fix our bus sitting were I could see him. We also had a good feeling about John D. (the owner).

At 7:45 AM I received clearance to move the bus to the last service bay (farthest from the street) and by 8 AM had the engine running and the tag axle up. Action Mobile Service has seven service bays, only one of which (#1) is inside. The other six are under a large roof with open sides. (It’s a Florida thing; you won’t see that in Michigan.) They wanted me to back into the bay so I had to reposition the bus toward the passenger side, swing the nose to the left and into the entrance gate, straighten out, back down to the bay, and then swing the back end in on the passenger side. Linda spotted for me, as she always does, and Bill signaled the final positioning.

Our coach at Action Mobile Service in Orlando, FL. awaiting the start of the driver side tag axle brake repair.

We were told yesterday that we would not be able to stay in the coach while Bill worked on it, but Bill said we could. The difference was that because the tag axle can be lifted they did not need to jack up the bus. That made for a more comfortable day, both for us and for the cats, and allowed us to be more productive than if we had been confined to the customer lounge. I spent part of the morning in the customer lounge anyway as I was on the phone with Prevost Parts US in Elgin, Illinois. I spent most of the rest of the day interacting with Bill and the two Johns. Linda, however, was able to use her computer in the bus and work on tax returns.

The brake was locked up to where Bill could not turn it by hand but he got the caliper off somehow and then removed the hub and rotor. I am always interested in how these things are done but figured that Bill, who did not know me, did not need me staring over his shoulder while he worked. When he finally got everything apart he determined that the brake pads and rotor needed to be replaced, as did the wheel bearings, races, and seals. The major problem, however, was going to be the disc brake caliper.

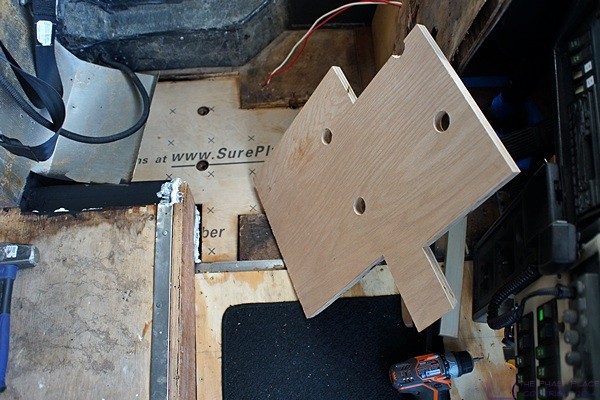

This is what a Prevost H3-40 tag axle looks like when it is completely disassembled.

Action Mobile called in Rex from Rush Trucking, a huge national trucking company. Rex had a heavy duty truck parts business at one time but sold it and went to work for Rush. He had been in the heavy truck industry for over 30 years and had a lot of expertise and contacts. He looked at the situation and determined the part numbers for all of the parts Bill needed. A couple of hours later he showed up with everything, including a rebuilt/remanufactured caliper. The only thing he could not get was a new torque plate (spider).

We could not determine if a new torque plate was needed but it was a possible cause of brake misalignment. If we were going to replace it, now was the time as it was completely accessible with the brake and axle hub removed. Gary at Prevost Parts had spent a lot of time with me during the morning and been especially helpful but I ended up talking to Wes to order the spider. It’s a phone bank and you usually have to take who you get as you cannot dial a specific person. You can leave a message and request a callback, but that can take a lot longer than waiting on hold for “…the next available representative.” They had a left hand spider in New Jersey and I ordered it for overnight delivery to Action Mobile. It is supposed to be here by 10:30 AM tomorrow morning.

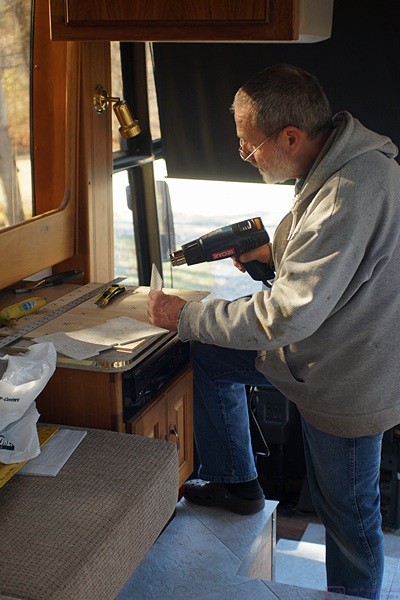

Without the spider Bill could not wrap up the job but he was able to spend the afternoon putting new seals and bearings into the axle hub and mounting the rotor to the hub. Once the spider arrives, and assuming it is the correct part, he figured it would take 90 minutes to put everything back together.

The new rotor mounted on the hub (just behind the red stool, and the new caliper (upper right behind the cardboard box).

John D. (the owner) said we could leave the bus in the bay overnight. We got to chatting and I gave him a tour of the inside. He noticed that we were not running a generator and asked if we were on an inverter. I confirmed that we were and he offered us the use of a 50 Amp RV outlet that was located by the passenger side rear of the service bay. It turned out that there was also potable water available if we needed it.

I waited until Bill was done working at 3:30 PM, so as not to interfere with his work, and then got out the shorepower cord and plugged it in. We do OK on the inverter, and can use everything with the genset running, but the coach is definitely most comfortable and useful when plugged in to shorepower, especially “50 Amp” (240/120 VAC) service. Although it was warm today, the coach was partly shaded by the bay and we decided not to run the air-conditioners. With the windows and roof vents open, and the exhaust fans on, our small Duracraft portable fan was sufficient to keep Linda comfortable.

By 5 PM everyone was done for the day and left, locking the gates on the way out. We had the lock code in case we needed to get out, or let emergency services in, but decided when we first arrived that we would not come and go unless absolutely necessary.

I had a lengthy conversation with Chuck about the status of our brake repair and what I was finding out about Prevost and parts availability in the process. I also texted some part numbers to Butch so he could pursue possible sources in northern Indiana and southern Michigan. While I took care of those communications, Linda made salads and a potato lentil curry for dinner. After dinner I talked to Pat and Vickie for a while and then called Butch and had a long chat with him. Linda was watching (reading, CC) our Thursday evening CBS TV programs and when I concluded my call with Butch I settled in to watch TV with her and work on my blog posts for the last several days.

2016/04/08 (F) Brake Away to WCRVR

I set alarms last night for 6:45 AM since Bill starts work at 7 AM and I told him yesterday we would be up and dressed by then and to not hesitate to work in/around our coach. I made a small pot of coffee and we had orange juice and bagels for breakfast which was made easier by the 50A RV electrical service that John D. had offered us late yesterday. There wasn’t much of anything Bill could do on our coach until the torque plate (disc brake caliper mounting spider) showed up. Linda worked at her computer while I worked on blog posts on my iPad.

I eventually put aside my blog work and gathered up some of the boxes the new caliper and other parts were in. I texted Butch with various part numbers I had been given by Prevost, gotten off of used parts, or copied from labels on boxes. He called me just before 10 AM to let me know the number on the box label appeared to be the one we needed. He was in contact with someone at ABC Bus Parts in Muncie, Indiana who was in contact with someone at Meritor. The information he was getting was that the caliper was not available in stock but I could get it for $1,200 with a 45 – 60 day lead time. While I was glad to hear that might be the case, it certainly contradicted everything I had been told by Prevost, which I found a bit disturbing.

The UPS truck showed up at 10 AM so I walked up to the office, retrieved the box, and took it back and set it by the driver side tag axle. I had just talked to Bill at little earlier but he wasn’t around at the moment. He still wasn’t around at 11 AM so I went to the office to see what was going on. As I suspected, Bill had to go out on a mobile service call. John D. (the owner) called Bill and then let me know that he would be back in about 10 minutes. I made sure everyone knew that I wasn’t trying to create an unnecessary since of urgency or priority for our coach, I just wanted to know what the status was.

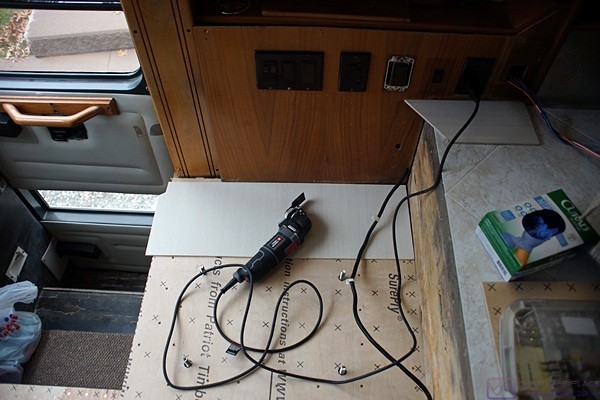

The new torque plate (spider) installed on the driver side tag axle. The new caliper is visible lower right. Action Mobile Service, Orlando, FL.

When Bill returned he got right to work and in short order had the new spider mounted. He then installed the hub, the outer bearing, and axle seal. The hub gasket and cap were last, after which he added hub oil through the hole in the sight glass portion of the hub. It takes time for the oil to penetrate the bearings and settle so some patience is required to get the correct oil level.

With the hub installed Bill now had to get the caliper in place. It’s both heavy and awkward to handle. It has to be lifted into place, lowered around the rotor, and secured with a pair of large steel slide pins. The problem is how to hold the caliper in place while getting the upper pin in place. In order to accomplish that he had another mechanic help him. He then adjusted the automatic slack adjuster and finally reconnected the air line to the brake “can” (actuator).

I left him alone until he was done and it was a relief to finally see that everything appeared to fit together. The hub spun with the minimum required drag, but we still had to test the installation. (The brake pads are always in contact with the rotor.) To do that I needed to apply and release the brakes but the tag axle was up (lifted) which cuts off the air supply to the brake chambers.

Lowering the tag axle releases the air from the brake chamber that powers the lifting mechanism and at the same time allows air into the air springs that support the weight of the coach on the axle. It also changes one of the air valves so that application of the brake pedal allows air into the tag axle brake chambers. I could lower the tag axle, and probably apply the brakes once or twice, with the air stored in the system, but raising the axle back up, and/or additional application of the brakes, would require me to start the engine. That required a few minutes of my time so Bill decided to take his lunch break.

The hub and rotor reinstalled along with the new caliper, ready for testing. Action Mobile Service, Orland, FL.

While Bill was eating lunch I checked with the two Johns to see if Rex could supply me with another left (DS) caliper and two right (PS) calipers. They checked with him and he said he could have two of them this afternoon but could not get the third one until Monday.

When Bill was done with lunch I started the engine and lowered the tag axle which caused the driver side rear to drop as the tag wheel/tire was not yet on the hub. When I applied the brakes Bill was not able to turn the hub and when I released the brake pedal he was able to turn the hub once again. That was the best test we could do with the bus sitting still and Bill was satisfied that the problem was properly repaired. Before Bill put the wheel/tire back on he climbed under the bus and greased the passenger side tag axle disc brake caliper. When he went to put the wheel back on the hub was too low. With the engine running I tried to raise the driver side rear using the Level Low system but it would not come up high enough. I tried lowering the front to pivot the tag higher but that did not work either.

Bill found a length of 4″x4″ timber, put it in front of the outside driver side drive tire and had me move the bus forward just enough to roll the tire up onto it. That raised the tag axle hub enough that he could get the wheel onto the studs and secure it. As soon as it was on I moved the bus forward a little more until the drive tire was off of the 4×4. The tag axle brake problem was fixed. Bill greased the two front/steer disc brake calipers and then checked the oil level in both of those hubs and the passenger side tag axle hub.

Now that I knew the disc brake caliper and spider fit and worked properly I let John D. know that I wanted the three additional calipers. He let Rex (Rush Trucking) know. We did not want to hang around Action Mobile in the bus until Monday and given that I would have to come back Monday in the car anyway I indicated that I would pick all three of them up then.

I settled the bill for the repair work. The amount was substantial but I knew what it was going to be so it wasn’t a surprise. I also considered it fair and had no problem paying it. A little over 48 hours before we come dangerously close to having our bus catch on fire and if it had it would have been completely consumed. In the hours that followed we were faced with the very real prospect that we might not be able to get our bus repaired, effectively rendering it useless as a motorhome. We even half joked about buying a lot in an RV resort, moving the bus there (towing it if necessary), and becoming Florida residents. It was a real low point from which Action Mobile restored our plans and dream for a long, adventurous retirement using our motorcoach.

As a separate transaction I paid a 50% deposit on the three brake calipers. At that point there was nothing left to do except say ‘thank you,’ hook up the car for towing, and leave, but not before calling Williston Crossings and making a reservation.

Linda usually handles the reservation/registration process but with her hearing and voice issues that has become my job, at least temporarily, but hopefully not long-term. Sometimes we have to Ieave a message and get a callback, but Joann answered the phone this time. We had decided that we wanted to stay through Tuesday evening and depart on Wednesday morning April 13. To our surprise there was no pull-through site available for that set of dates. Site #439 was available, however, and was actually our 1st choice anyway as it is next door to our friends, John (Smiity) and Ali, and is the same site we were on for our entire winter here in 2014. I made the reservation, which was very easy as the resort still had our information on file.

With our camping arrangements made Linda texted Smitty to let him know we were getting ready to head his way. I started the bus and pulled it out of the bay and around to the passenger side while Linda spotted for clearance to obstructions. I pulled up by the office, lined up with the gate, and shut off the engine. Meanwhile Linda brought the car up behind the bus and we connected it for towing. We checked that all the lights were working and were ready to go. We worked our way back the short distance to US-441 / Orange Blossom Trail via Satellite Blvd and the Central Florida Parkway. From there it was only a little over a mile north to get back to the entrance to FL-91 (Florida’s Turnpike). We had already studied the route on our iPad Maps app so we knew it was an easy interchange, with all turns to the right. As long as we stayed to the right we would end up northbound on the Turnpike towards I-75 and Ocala.

Because I wanted to make sure I stayed to the right I ended up going through a manned tollbooth rather than the usual SunPass Only lanes. The staffed lane was also marked for wide vehicles and was also a SunPass Lane, so it was not a problem. It only caused a brief moment of confusion as the attendant started counting axles. I pointed to our transponder but he did not see me and I pulled on through as soon as the electronic sign said “SunPass Accepted.”

Traffic on the Turnpike was not too bad but we did see an electronic information sign shortly after getting on advising of traffic congestion between the FL-301 exit and the I-75 merge. No surprise there, especially on a Friday afternoon. I rolled along initially at 62 MPH while Linda kept a close eye on the temperatures of the four wheels/tires that have disc brakes (steer and tag axles). The DS tag was running hotter than the other wheels by at least 10 degrees F, including the PS tag; not enough to indicate a problem, but given our recent experience and with no meaningful miles on the repair work, we were understandably nervous. I decided to error on the side of caution and travel at 55 MPH.

Linda checked the temperatures every few minutes for the entire trip. The steer tires/wheels and the drive tires/wheels eventually settled in to temperatures in the mid-90 degree F range, plus or minus, while the tag tires settled in around 105 degrees F while free-wheeling and got as high as 120 after braking. The temperatures came back down, however, which was important, and the passenger side was sometimes higher than the driver side, which either meant the driver side was working or the passenger side was starting to fail. I preferred the former possibility to the later but it wasn’t like I had a choice.

As we were warned, the traffic on the Turnpike slowed to stop-n-go conditions starting at the exit for FL-301. It remained congested, very slow, and often completely stopped all the way to the merge with I-75 northbound, where it got even worse (if that was possible). The volume of traffic trying to move north was as astounding as its lack of movement and remained heavy all the way to exit 354 at Ocala where we finally left I-75 and headed northwest on US-27 towards Williston.

Linda had texted several status updates to Smitty and at 5:05 PM texted him again as we turned off of US-27 / Main Street onto NE 5th Street. I stopped at the turn into the resort and lifted the tag axle before proceeding around the corner. As I came around and pulled up to the gate Smitty was coming the other way in his golf cart. We said a quick ‘hello’ and he opened the gate. I pulled up by the office, which had closed just minutes before, so our bus/car combination was not blocking the incoming traffic lane and shut off the engine. We unhooked the car and Linda moved it to a temporary parking spot. John and I discussed how best to get me into the site. I expressed my preferred approach and he agreed to try it. I then followed him to the site where Linda was waiting for us.

I learned a lot about how to maneuver this bus two years ago from ‘Big Bill’ Cowick when we were parked next to him and Nancy at Suncoast Designers in Hudson, Florida. Smitty got me positioned correctly to start backing up and watched the front end while Linda watched the rear end. I was able to back it up around the corner of an intersection and angle it towards the site, coming very close to a recently added street sign on the passenger side without hitting it. Once the right front corner was able to clear the sign I turned the steer tires to the left, tightening the turn as I went, while watching John, Linda, and the concrete pad in my mirrors and rearview camera. I backed the bus around smoothly onto the pad and then pulled forward once to make sure I was straight and the distance I wanted to be from the driver side edge of the pad. I then backed up to where the tag axle tires were still fully on the concrete pad with only a foot or so to spare. That positioned the bus conveniently for utility hookups while leaving plenty of space to open bay doors and lots of room on the passenger side where the patio area is located. It also created plenty of space in front of the bus for the car, getting it well clear of the road.

Ali and John were already at Jeff and Kathy’s when John drove up to let us in. With the engine still running and the tag axles still up I checked that both tag axle tires spun freely. They did, which was very good news, so I lowered the tag axle, leveled the coach, and shut off the engine. I disconnected the chassis batteries, turned off the auxiliary air to the engine accessories, plugged in the shorepower cord, and made sure the auxiliary air-compressor was turned on. While I was taking care of all that Linda prepared a few things on the interior, opened windows and ceiling vents, and got a Yuengling lager out of the refrigerator and put it in an insulated cozy for me. It was time to relax and go be sociable at Jeff and Kathy’s 5th wheel.

Everyone wanted to hear about our recent “adventure,” of course, and the telling of the tale fell to me. At some point my beer was gone so I walked back to our coach and opened our bottle of Nutura Carmenere, a red wine I picked up at Publix in Cocoa Beach along with a Nutura Merlot. It was not a brand we had tried before, and I had never heard of a Carmenere, but they were $11.99 per bottle wines on sale 2 for 1. We are always on the lookout for red wines that I like (not dry, no tannins) and are willing to risk $5 to $8 to try one. Not surprisingly, the Carmenere was drier than I like, but I was able to drink it and I got to show everyone one of our polycarbonate wine glasses.

We stayed and chatted until 7 PM when everyone was finally hungry and we all returned to our coaches to have dinner. After dinner I sent a brief text message to four people just to let them know that we made it to Williston without any difficulties and that I would fill them in on details tomorrow. We were planning to go next door to John and Ali’s 5th wheel after dinner and sit around a campfire but we did not see them outside and we were very tired. I aimed the front TV antenna towards Gainesville and we found something to watch. Linda was off to bed before 10 PM and I was in bed by 11. It had been a long day and we were glad to have it behind us and be back at WCRVR.

2016/04/09 (S) Water Pump Down

In spite of being very tired I stayed up late last night watching back-to-back episodes of Ken Burns’ JAZZ. Linda went to bed around 10 PM and I turned in at 12:45 AM. She was up at 7 AM and walked to the bath/laundry building to take a shower while I slept in until 8:30 AM. I was going to walk over and get a shower as well but Linda informed me that the water never got more than lukewarm. No thanks. I decided to hang out in my sweats for a while, made a pot of coffee, and worked on my blog posts for the past week. With all that has happened I have had quite a bit to write about.

I plugged our WiFiRanger in last night and it did not have any difficulty connecting to the resort Wi-Fi system. The problem we seemed to be having this morning was that our devices will not stay connected to the WiFiRanger. Nuts.

Linda needed to continue working on taxes and set her computer up on the desk. I have not taken my computer out of its case since I packed it up on Wednesday morning but I will have to get it out sometime soon. Our fresh water level finally dropped below 1/3 tank so I will need to hook up the water softener fairly soon but decided I would do the laundry and get a shower first. I gathered up all of the soiled clothes, towels, and some of the bedding, along with the tote bag of laundry supplies and the tote bag of shower supplies. I loaded everything into the car and drove to the north laundry/shower building, which is better equipped than the one near our site. It was noon.

No one else was using the laundry so I used three of the washing machines closest to the dryers. These washing machines take about 25 minutes to run through their cycle so it was just over half an hour before all three loads were done. The dryers run for about 45 minutes, so once I had the laundry transferred to the dryers I took a shower. I then drove back to our coach, dropped off the shower supply bag, and we stripped the bed. I returned to the laundry building, washed the sheets, and transferred them to a dryer. As each dryer load finished I moved it to a large table and folded or hung it up. By 3 PM I had everything neatly packed back into the nylon mesh laundry bags and returned to our bus.

Linda helped me get the laundry inside and put away. I then turned my attention to refilling our fresh water tank. That is a bit of a process as I have to get out the pre-filter, with hoses and pressure regulator attached, and the water softener, again with hoses attached. Heavy, bulky, awkward, etc.; it’s my second least favorite RV chore, right behind checking tire pressures. I got everything connected and turned on the water supply. The connection at the supply faucet and the connection at the coach inlet both leaked badly. I snugged up the coach inlet connection so it didn’t spray water. It was still dripping quite a bit but it was good enough for filling the tank. I opened the fill valve, heard the water flowing into the tank, and opened the door to have a look.

The remote gauge had dropped below the 1/3 tank level a day or so ago so all we could tell from the house systems panel was that we had less than 40 gallons in the tank. I had noticed this morning that we were not getting the usual flow of water to the toilet and Linda tried to use the kitchen faucet late this morning and got no water. Although I did not think we had used that much water we both made the (naïve) presumption that we had run the tank dry. To my surprise (not really), the tank was at the 1/4 level, which meant it still glad about 30 gallons of water in it. That seemed to suggest rather strongly that the problem was something connected to the water pump. Not good.

I shut off the water and started grousing, because I find that it makes me feel better and is part of my problem-solving process. So does swearing a bit, so I did some of that too. Not like a sailor, of course; I was a USAF ROTC cadet years ago, after all. There were a few obvious things to check, after which I figured I would call Butch if they didn’t pan out.

I got out my multi-meter and then looked up the circuit numbers for the water pump and switch circuits. I checked those circuits in the 12 VDC distribution panel and they all had +12.7 VDC which meant the fuses were OK. The power to the pump is switched through a relay so that the pump can be turned on/off from multiple locations using momentary contact switches. The easiest way to check the proper operation of the relay and confirm/deny the presence of power at the pump, was to disconnect the + 12 VDC and return wires from the pump and check for voltage on the supply wires. With the relay “off” there was no voltage present (a very small mV reading). With the relay “on” I had 12.7 VDC. Relay off, no voltage. That pretty much meant the water pump was down.

While not a crisis situation, this failure, at this time, and on the heels of all of our other recent problems, was certainly unwelcome news (not that any failure at any time is ever welcomed). The only upside was that we were at a nice RV resort with full hookups, in a familiar location with relatively convenient access to resources, and in the company of friends. We had city water available, so we could use all of the systems on the coach that required fresh water, and we were scheduled to be here for four more nights, which meant I had time to deal with the problem, including getting parts shipped here if needed.

My first instinct, however, was to try to get this fixed RIGHT NOW! I called Smitty to see if there was any place in town that sold RV parts. As I expected, he directed me to the local ACE Hardware store. I knew from previous visits that they carried some RV parts but were unlikely to have 12 VDC water pumps, and even less likely to have the exact model I wanted/needed.

Linda did a Google search and located a Camping World store in Summerfield, Florida south of Ocala. Not that I was eager to go to Camping World, the home is “list price plus,” but if they had the right pump (or any pump) in stock I was feeling like it would be worth paying the premium to get it and have the problem resolved quickly. Unfortunately (or fortunately), it was already 4 PM and the store closed at 5 PM. There was no way I would make it in time, so I returned my attention to making the coach usable from the city water supply.

In order to operate off of the city water supply we would need to leave the water turned on, and in order to do that I needed to get the connections to not leak. While I probably had replacement washers in one of my parts boxes, I decided to go to ACE Hardware for washers just on the chance that they might have an appropriate water pump.

The only pump at ACE that would have worked was a 120 VAC unit and I was tempted to buy it. In fact, when I redo the water bay I will install redundant water pumps and I am seriously considering keeping the 12 VDC pump and making the second one a 120 VAC model. For now though, replacing the DC pump with an AC pump would involve more work than I wanted to get involved in. I did find what I was really looking for, however; garden hose washers. I bought two different kinds of flat washers, vinyl and rubber, and a pack of vinyl strainer washers. I should have also bought a roll of Teflon tape, but I did not think of it at the time. Back at our rig I realized that I was probably going to need Teflon tape. I was sure that I had some but it was not in any of my four tool boxes. Linda helped me empty out the car until we finally found the correct parts box.

I replaced the strainer washer in the pressure regulator fitting that attaches to the water supply as the existing one was damaged and badly deformed. I also wrapped the supply faucet threads with Teflon tape before attaching the regulator to the faucet. With the output of the regulator valved off I turned on the water supply. Voilà; no leaks!

The strainer is the first line of defense against particulate matter getting into the regulator and clogging it. When I redo the water bay, plan to set up the plumbing so that the supply water goes through a particle filter before going through a backflow preventer (check valve), an adjustable regulator, a water softener, and additional filters, all of which will be installed in the bay but easily accessed and serviced. I might even install an inline UV sanitizer. The only thing I will need to do to connect the coach to a water supply will be to connect a hose at both ends. Priceless.

The other leak was at the fitting in the bay where the hose gets connected. These garden hose fittings are cheap, easily deformed, and prone to leak, and I think they are one of the other “weak links” in the materials and systems used to make RVs. (Sewer hoses and connectors are probably the worst, but that problem has been solved by Lippert Systems and I will be using their technology when I redo the utility bay.) Replacing the flat washer periodically is necessary routine maintenance but easily overlooked until a problem develops.

I replaced the existing flat washer with one of the vinyl ones and then taped the threads on the (male) end of the hose with Teflon tape. I carefully threaded the two pieces together finger tight and then just a little tighter with a pair of slip pliers. (Over tightening actually deforms the washer and causes it to eventually leak.) I opened all of the intermediate shutoff valves and Voilà; again, no leaks! Our coach was now usable and we could leave the water on unless we were both going to be away from the coach for an extended time, when even a small leak could quickly become a big disaster.

Time to relax. John and Ali were already down at Jeff and Kathy’s and Linda already had a Yuengling lager in an insulated cozy ready for me. We took some peanuts along and walked the short distance to their site to sit a spell and visit. Earlier in the day Jeff and Kathy had gotten a new dog and Kathy was out walking it. They lost their Yorkie, Teddy, to cancer back in December and were not really planning on getting another dog so soon but an elderly gentleman, who lives alone in the resort, had a 3-year old dog that he was no longer able to car for and needed to find a home for it. The dog’s name is “Mandy” and she is an 8 pound Dachshund / Miniature Poodle mix. She has a Dachshund body size/shape and face but a silver gray, slightly wiry coat unlike any Dachshund I have ever seen. She was friendly and sweet tempered and from all appearances she will settle in with Jeff and Kathy very easily. While dogs get strongly attached to their owners, they also respond quickly to the kindness of strangers.

I think we were there for at least 90 minutes, perhaps two hours, before everyone got hungry and returned to their rigs for dinner. By that time it was already 7 PM and we were headed to John and Ali’s 5th wheel once we ate, so Linda made a quick, easy dinner consisting of a nice greens salad and Amy’s Asian Noodle frozen/microwaved entrées.

After dinner I called Butch and brought him up to speed on our disc brake situation and told him about the water pump. He and I shared the opinion that it seemed like something might have happened with the +12 VDC power supply to the coach. Most of the house DC power circuits and systems, however, appeared to still be OK. He reminded me that we have an Amazon Prime account and could probably get a new pump delivered to the resort by Tuesday for a much better price than at Camping World. Roger that. I let him know that our current plan was to leave WCRVR Wednesday morning and arrive at their place in Twelve Mile, Indiana on Friday. He said we should go ahead and park and plug into the electrical power if they were not there as they would be setting up for a local hamfest that evening over at the county fairgrounds across the road from Bill Tharpe’s place in Mexico, Indiana. Been there, know how to find it.

We walked next door to John and Ali’s around 8 PM and I took another Yuengling with me. It’s been that kind of week, I guess. They have an elevated propane firepit, conveniently located under their patio awning, and had chairs arranged around it in a conversational grouping. We sat and talked until 10 PM, when John had to make the rounds to close up certain buildings and check the gates. We continued to chat with Ali while John took care of his chores and he was back within 30 minutes. By 11 PM Linda was finally too tired to be sociable, went back to our coach, and went to bed. I stayed until almost midnight and finally left when I was yawning more than talking. I went to bed fairly directly and went right to sleep.

2016/04/10 (N) Water Pump Prime

We got up this morning when we were ready and not a minute sooner. I made coffee using the two new bags we bought at the Sunseed Co-op in Cocoa Beach. I requested pancakes for breakfast and Linda obliged by making some very good ones.

Last night I was thinking about driving to Camping World in Summerfield, south of Ocala, today to buy a new water pump. The store opened at 11 AM and I figured I would find a pet supply store and buy some cat food while I was out. After Butch suggested last night that I could probably find the exact pump I needed through Amazon, I searched for it and he was right. I ordered it with four hours to spare to qualify for next day delivery with an $8 upcharge so I would have it on Monday. Standard Amazon Prime 2-day free delivery would have had it here on Tuesday, but I did not want to risk having it show up late in the day or worse, having the delivery truck get here after the office closed or not get here at all.

I had hoped to spend some time at my computer working on the blog but the best I was able to do was get it turned on, connect it to the Internet, and download my e-mail, which I had not done since Wednesday morning. I was more than a bit surprised that I had over 80 MB of attachments! The bulk of that was several very large photo files from our daughter having to do with some recent projects our grand-daughter Katie was involved in.

I called Chuck around 1 PM and caught him standing in line at a Cracker Barrel restaurant. We chatted briefly while he and Barb waited to be seated and I filled him in on the latest developments in the Prevost air disc brake saga.

We had an early dinner after which we emptied out the car and the passenger side of the front bus bay to rearrange where things were stored and make room for the three new air disc brake calipers and the old one. Linda brought the bathroom scale out and we weighed the old one as best we could. I would have sworn it was 100 pounds but the scale said it was only 63 pounds. That was good as four of them would only put 250 pounds in the car instead of 300 to 400 pounds.

We were able to repack the bus bay better and more quickly than I expected. We put smaller, lighter boxes back in the car, got our beverages, and walked down to Jeff and Kathy’s 5th wheel for happy hour. Jeff’s brother, Mark, was there and we learned that he lives in an apartment over by the Williston airport. Jeff made hamburgers for everyone (except us, of course) and we stuck around while they ate dinner. Jean showed up not long after everyone was done eating and joined the conversation.

Smitty had to lock all of the gates at 5 PM so I rode along while he made his rounds. Linda and I left around 7:30 PM, as the light was just starting to fade, and went back to our coach. We had a light dinner/snack of pretzels and hummus and shared a very delicious orange. I called Butch and chatted briefly with him about the water pump and brakes and our revised travel plans. As things now stand we plan to leave here Wednesday morning and get to their place in Twelve Mile, Indiana sometime on Friday.

At 8:15 PM we walked next door to John and Ali’s 5th wheel and sat around their propane firepit. Smitty had made popcorn with peanut oil and Hawaiian sea salt. Yum. John had to lock up the resort buildings at 10 PM. Linda and Ali were both tired and ready to go in for the night so I rode along with John. Once we were back we retired to our respective rigs for the evening. Linda was watching Elementary on TV so I picked up the story line in progress. When it was over at 11 PM we went to bed and went right to sleep.

After dinner we made the short trip to Madeline’s house and arrived at 6:30 PM. Linda got Madeline into her pajamas while I brought all of the stuff in from the car and turned up the thermostat.

After dinner we made the short trip to Madeline’s house and arrived at 6:30 PM. Linda got Madeline into her pajamas while I brought all of the stuff in from the car and turned up the thermostat.