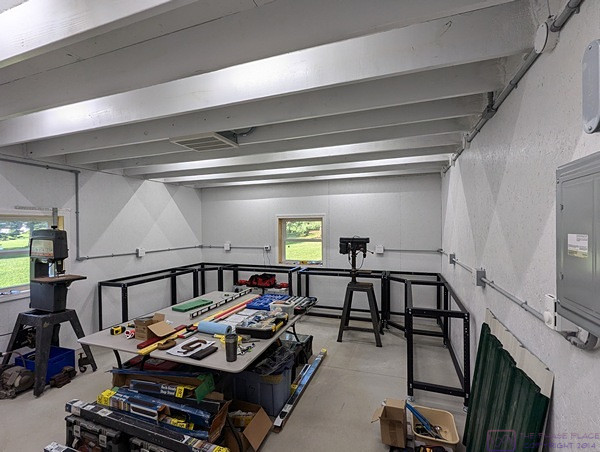

[ Note: This is a long post without any photographs. There will be a separate update post, with photos and captions, about the accessory building (barn) project. ]

TUESDAY 11 October

The driving portion of our grand tour of Eastern/Atlantic Canada and New England ended yesterday, but the trip itself wasn’t really over until all of the post-trip tasks had been completed. This post covers the seven (7) days following our arrival back home. A big part of returning home, of course, was the accessory building (barn) we were having built in our absence, but I will cover things related to that in separate, ongoing posts.

Top of the list was emptying out the trailer and moving back into the house, much of which we did as soon as we got home, and some of which I described in the post for October 10. But there was a great deal more to do than I described there, and today we continued with the “things that must be done.”

Foremost for us was washing and Walbernizing the Airstream, as the weather forecast was for a dry, partly sunny day with an afternoon high temperature in the 70s (F). But it wasn’t the only thing on the list; high on my list was laundry. After coffee and bagels for breakfast, I sorted the soiled laundry into the requisite categories (white-hot, white-cold, dark-warm, dark-cold, bedding/linens-warm, and blankets/bedspreads-cold), and put the white-hot load in the washing machine.

Washing the Airstream wasn’t a matter of simply turning on the outside water. I had to get the tall (8’) step ladder out of the shed, along with the 100’ hose/reel and one of the wheelbarrows (to use for moving stuff between the trailer and the garage). We have a 2-tank water deionizing system, so I had to get that out of the library. Other items included: McGuire’s Automotive soap; the spray nozzle for the hose; the long-handle brush; the bucket for soap; and the medium (6’) step ladder, all of which had to be moved from the garage to the wash area in the driveway in front of the house (where the water faucet is located, and the gravel drains well). And, I still needed to empty the three outside storage bays in the trailer, and empty out the back of the F-150. Linda helped with many of these tasks, of course.

On top of all that, our barn builder (Chuck) was due to come by today to meet with his insulation sub-contractor (Mike), and then meet with us. He texted me mid-morning to let me know that he and Mike would be here at 11:30 AM. Tuesday was also grass mowing day, so our lawn care guy (Keith) would be showing up sometime around noon. We have not seen him since the Tuesday just before we left in June, so we knew there would be some catching-up conversation. Besides maintaining the yard, Keith had sent occasional photos of the progress on the barn. At a minimum, he had already mowed more times than we prepaid, so we owed him payment for services rendered.

But I digress. We wrapped up our conversation with Chuck, as described in the separate post on the barn project, and he went on to his next appointment. By then, it was lunch time, so we had grilled cheese sandwiches. Very tasty. I transferred the laundry from the washing machine to the clothes dryer, and then we turned our full attention to washing the trailer.

While not as big as the bus, it was still a lot of work. I started with the roof (of course), which required me to work from the 8’ ladder. Even then, it was sometimes an uncomfortable reach to get to some of the areas, and almost impossible to reach others. For as streamlined as the Airstream trailer is, the roof is littered with stuff that is not very aerodynamic, and is hard to clean. Too make matters more difficult, walking on the roof is ill-advised, and you have to be very careful where you step.

Linda stayed on the ground (she doesn’t like ladders) and managed the soap bucket, brush, and hose. The procedure was as follows: climb the ladder, get the hose from Linda, spray an area, give the hose back to her, get the soapy brush from her, scrub the rinsed area, give the brush back to her, get the hose from her, rinse the area I just washed, and give the hose back to her. Climb down the ladder, move it to the next location, and repeat; at least a dozen times, probably more.

(Once we have the bus and the trailer in the barn, I will be buying a taller step-ladder, probably 14 feet, and some sort of adjustable platform that can go between two ladders to provide a stable work surface. Alternatively, I might but some scaffolding with wheels.)

Once the roof and the end caps were done, I could reach the rest of the body from the ground. Working from the top down, I did the upper half and then the lower half. (This is not true for the bus, as the upper half still requires a ladder or work platform.)

We were busy enough all day that I wasn’t keeping a close watch on the time. I think we actually started washing the trailer around 1 PM and finished sometime around 5 PM, but that included an extended time-out to chat with Keith. It was probably 5:30 PM or later by the time we had cleaned up our equipment and put everything away. But the trailer was clean and ready for the Walbernize One-Step Cleaner & Sealer.

AMAZON was having their 2-day pre-something-or-other event today and tomorrow, so Linda put some things in our cart. Among them was a new 2-slice toaster with openings wide enough to toast bagels. It also had a bagel setting, so it would only toast on one side, essential for proper bagel toasting. She also ordered a new frying pan, some baking sheets, and a pair of adjustable carbon-fiber walking/trekking poles. I had been keeping an eye on a propane tank level monitoring kit. It was still available, and still on sale for the same price I had seen previously, so I investigated a bit further into how it actually worked. It turned out to use sonar, and was made by a company that makes various products using this technology for industrial applications, so I put it in the cart as well.

As I did not finish the post for this day until a week later, I no longer recall what we had for dinner, but whatever it was, I’m sure it was delicious, as always. Being Tuesday, after dinner we watched the FBI shows on CBS.

WEDNESDAY 12 October

The forecast for today was for intermittent rain with cooler temperatures and overcast skies. We had planned to treat the exterior aluminum on the trailer today with the Walbernize One-Step RV Cleaner & Sealer, but the weather was not conducive, either to the task or to our mood for doing it. We were both a bit tired after the last two days, and decided to take it easier today. Besides, I still had laundry to do, and wanted to work at my desk for a while to wrap up my blog post for Monday (October 10th).

I needed to get the F-150 in for service, specifically to have the brakes checked/repaired, so I called Brighton Ford and made that appointment for Monday 24 October. We also needed to pick up Linda’s car, and our mail, from our daughter’s house, and drop off some gifts we had picked up in our travels. Linda contacted her to check on timing and the reply was “any time after noon.” It’s a nice, 45-minute, drive in the country to get to her house, so we timed our departure to arrive around 12:30 PM.

Before we left, however, I noticed a blue car in the driveway by the barn, so I walked down to see who was there. There was at least one other vehicle there, and it was the lead carpenter and his two assistants. I introduced myself and we chatted for a few minutes and then I left them to their work, which I will describe in separate posts about the barn project.

We visited with our daughter for a bit, but did not overstay our welcome as she was in the middle of a project. She is redoing floors (wood and tile) and bathrooms (vanities, fixtures, wallpaper, etc.) and has already redone most of the lighting and installed smart switches and dimmers throughout the house. She also put in remote controlled window shades, and has done a lot of painting. She’s incredibly handy, has excellent taste and color sense, and is meticulous in her work.

On the way home, I ran some errands while Linda did some grocery shopping. I topped up the fuel in the F-150 ($4.49 for regular / 87 octane) and then got the truck washed. I used the same drive-through car wash I have used for a long time, but this time the final overhead brush in the drying area bent my antenna in two places. That had never happened before, so something had obviously changed with their equipment. But it won’t happen again, at least not there. I did not even bring it to their attention (there would have been no point) and instead drove directly to Brighton Ford to see if I needed to add this to my service list for the 24th. It turned out to be an easy, user-serviceable, job to replace the antenna, so I went to the parts department to get one. They were on back-order (of course), so I ordered (and paid for) one. I picked up a pair of replacement windshield wiper blades while I was there, and replaced them as soon as I got home.

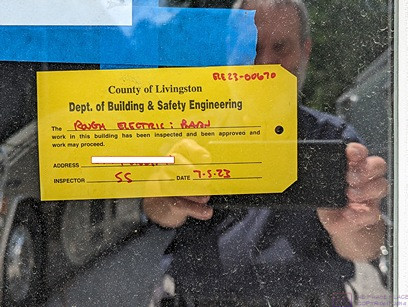

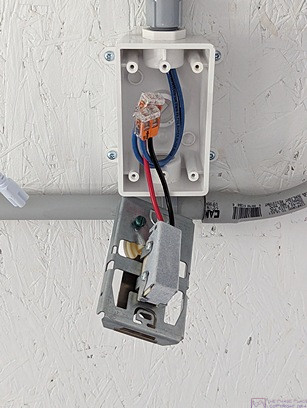

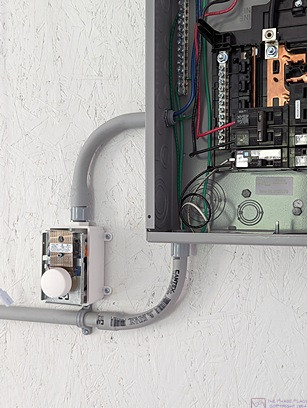

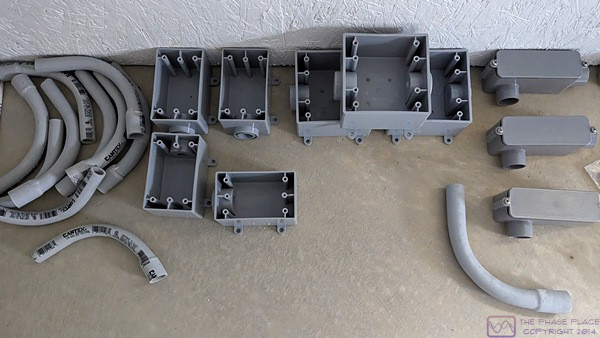

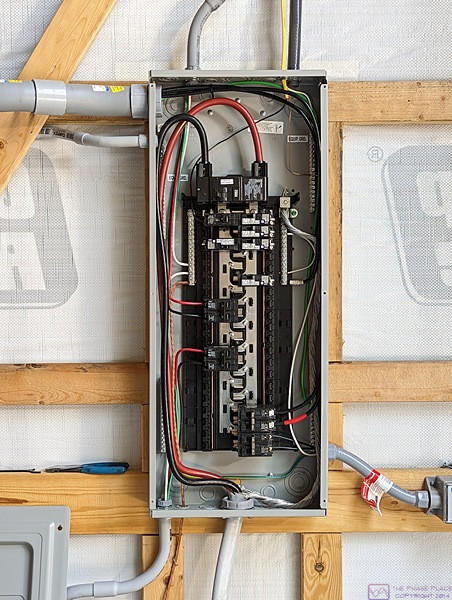

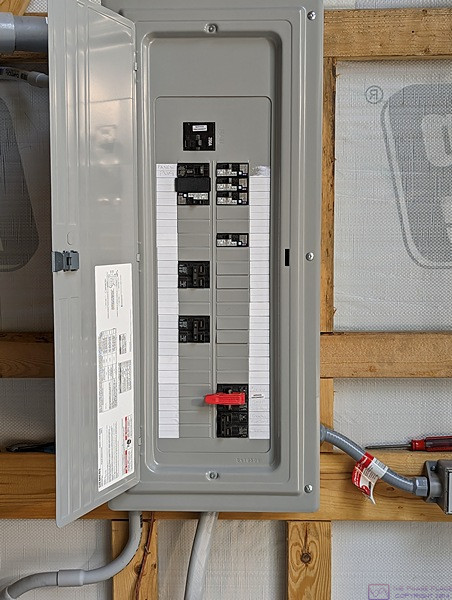

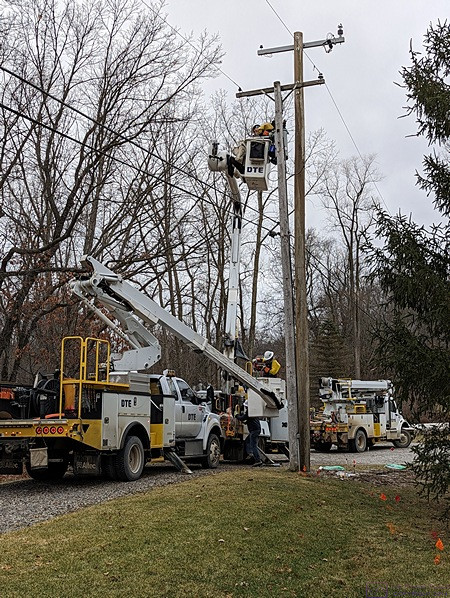

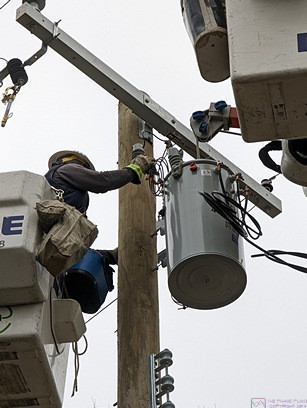

Back at my desk, I finally managed to get on the DTE website and located the information I needed on the process/procedure for getting electrical power to the barn. I printed off the instructions and called one of the indicated numbers, but it was already after hours, so this had to wait until tomorrow. I will cover the details of this in my accessory building project update post, as all of this has to do with the barn project.

I did contact our friend, and fellow bus owner, Chuck (not-the-builder) to arrange a dinner get-together so we could catch up with him and Barb. Saturday, 5 PM was agreed upon at the La Marsa in Brighton. I also contacted our friend, and my former co-worker, Kate about getting together. Tuesday the 18th was agreed to, with the place TBD. Part of being gone for so long is that we were eager to reconnect with friends and family in person and (hopefully) they with us.

For dinner, we had breaded chicken cutlets, brown rice, and corn, with turkey gravy. All vegan, of course, and all very tasty and satisfying.

After dinner, we had a ZOOM call with Paul and Nancy. They had finally taken delivery of their 2022 Alliance Paradigm 370FB 5th wheel trailer (RV) and had it delivered to the RV park in Gulf Shores, Alabama, where they plan to keep it, and will have it moved in/out of storage seasonally for their use. They had been busy getting the things they needed for it, and getting it set up to live in. It was great to chat again, and get a real-time video tour of the interior. It was very nice, of course.

Wednesday is not one of our regular TV nights, but this past Sunday we missed the 3rd/final episode of Van Der Valk (for the season), so we streamed that. It was followed by an episode of NOVA on Computers and Crime, so we watched that as well, and then went to bed.

THURSDAY 13 October

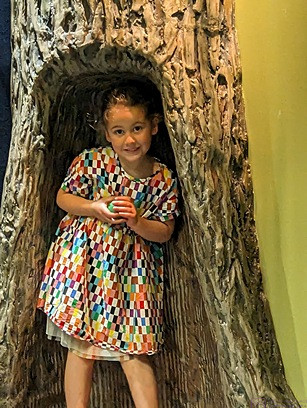

Today was someone’s 4th birthday; Happy birthday, Sadie Rose! She was in pre-school all day, of course, so a happy birthday Facetime call had to wait until after dinner.

The weather forecast still had a possibility of rain today, so we deferred the Walbernizing of the trailer for another day. Our main focus instead became finishing the job of completely emptying the inside of the Airstream and then thoroughly cleaning the inside as well as everything that had been stored in it, especially items that had to do with food (storage, preparation, consumption, cleaning, etc.). That also included laundry, of course, which I continued to work on. Before that happened, however, I was able to chat with Erich, the Service Manager at Woodland Airstream, about our upcoming appointment and list of issues, most notably the furnace and the transverse hump/bulge/ridge in the kitchen floor.

Breakfast was waffles with some of the Maple Butter we got at Domaine Acer in the Gaspé Peninsula. It was just as delicious as we remembered, and brought us back briefly to the wonderful discovery of that place and its products.

After breakfast, I called the DTE phone number in the instructions. Actually, there were two phone numbers, one for commercial and one for residential. I called the commercial number first. The voice menu made it fairly obvious that it was for builders, and that I needed to call the residential number, which I did. I will cover the details of the conversation, and follow-up actions in my accessory building update post, as all of this had to do with the barn project.

As long as we were on a roll, we both logged in to our MyChart app on our iPads and set up our Annual Medicare Wellness Visits with the HFHS Columbus Medical Center Internal Medicine Department in Novi. Our primary care physician retired in July, so we will both be seeing new, and different, doctors now. I then used the CVS app on my iPad Pro to schedule both of us for our seasonal flu shots and the newest bi-valent CoVID-19 booster next week.

We also did a partial winterization of the fresh water system and the drain traps in the Airstream, which went something like this: Drained the fresh water tank; Opened the hot and cold low point drain valves; Removed the drain plug from the water heater; Used an air-compressor to blow out the fresh water lines and water heater as best we could; Drained the little bit of water in the gray tank (onto the ground); Filled the two sink traps and the shower trap with enough potable antifreeze to make sure some of it ended up in the gray tank; Added potable antifreeze to the toilet flushed it into the black tank, and left some on top of the valve to keep the seal moist. (The reason for the antifreeze in the waste tanks was to keep the knife valves from freezing if there was any residual water left in the tanks.)

Lunch was leftovers (chicken cutlet with gravy, rice, and corn). Yum.

We were done working on the trailer by 5 PM, and ready to quite for the day. We continued to be amazed by how much stuff we had brought into the house and garage as a result of emptying out the trailer and truck. Linda continued to sort and separate stuff, setting aside things she does not intend to put back on board, and ran several loads through the dishwasher. We wanted everything to be clean before we packed/stored it until the next time we use the tailer. And at this point, we do not yet know when that will be, exactly or even approximately.

I was still working on this post the following week, and no longer recall what we had for dinner. Whatever it was, it was undoubtedly good, after which we Facetimed with her Sadie, and sang happy birthday to her.

We didn’t have any Thursday evening TV programs we were watching at this point, so we streamed Masters of the Universe – Dr. Strange: The Multiverse of Madness.

FRIDAY 14 October

Around breakfast time, I got a call back from Sharon in the DTE Northwest Planning office, regarding the service request I had initiated yesterday. More details about this call will be in the separate update post about the accessory building project.

Late morning, we finally got around to putting the Walbernize One-Step RV Cleaner & Sealer on the exterior of the Airstream. It was cooler than we would have liked, and a bit breezy, which wasn’t great. But it was also cloudy, which was good, as the product is not supposed to be applied in direct sunlight. I worked on the upper half of the body, using a ladder, while Linda worked on the lower half from the ground. It was an easy enough product to use: wipe on, let dry to a haze (doesn’t take very long), and wipe off, always working with the grain of the aluminum. The results are always very nice, and the body is slick to the touch afterwards, it’s just a lot of surface area and takes a while.

I was still working this post on Tuesday, the 18th, so I no longer recalled details of what we had to eat today, or other such minor considerations. I do recall that after dinner we watched an episode of Star Wars: ANDOR and The Lord of the Rings: The Rings of Power and then the latest episode of The Great British Baking Show. Our tastes in TV and movies are, if nothing else, eclectic.

SATURDAY 15 October

We were finally getting back into our normal “at-home” routine, starting the morning with coffee and our iPads. Saturday mornings are also the weekly breakfast gatherings of members of the South Lyon Area Amateur Radio Club (SLAARC). We did not go today, but I am looking forward to resuming our attendance at these gatherings.

Breakfast was scrambled eggs (Just Egg) with bacon, two slices of toast (expertly toasted in our new toaster), and an orange, split equally between us. There might have been orange juice involved as well, but I don’t recall at this point.

We had enough recyclables to warrant a trip to Recycle Livingston. Our membership had expired last month, so Linda made out a check for the renewal before we left.

My existing site plan for the barn project did not include a few pieces of information that DTE needed. I spent part of the day modifying my QCAD drawing to include those features and e-mailed it to the DTE planning consultant (John). Further details about this will be in the accessory building project update post.

The final task in cleaning the Airstream was to apply 303 Aerospace Protectant for the window and door seals, and adjust one of the window latches. It was chilly outside, so this was a less-than-completely-comfortable task, but I got it done. Except for the seals for the three bay doors; I forgot to do those, and just let it pass for now. The window seals tend to stick, but the bay seals do not, so it was merely for preventative maintenance and could wait until spring.

We both got showers and left around 4:40PM to join our friends, Chuck and Barb, for dinner at La Marsa. It was great to see them again. We were glad we could all fit in dinner as quickly as we did, as they have an early November departure planned for their winter RV resort in Naples, Florida. They plan to be back, however, from Thanksgiving to New Year’s, so we should have another opportunity to get together with them yet this year. The meal (food), however, was a disappointment.

We both had Koshary, a dish we have had many times at this, and other La Marsa locations, and it was not as good as normal. The caramelized onions they put on top had been burnt to a crisp and were not tasty. The dish has always included some amount of capellini (angel hair or fine pasta) but this time seemed to be made with spaghetti, which was too thick, and there was too much of it. Linda also thought it had too much tomato paste, so both the taste and texture were “off.” We didn’t complain, but I doubt that we will order it again any time soon. They have other things on the menu that we can eat, and like, so we have not given up on the restaurant. We were reminded, however, of how quickly a restaurant can lose their regular customers if someone is not paying attention to the consistency and quality of the dishes, especially ones (like Koshary) that are both signature items for this chain, and a dish we have never seen on a menu anywhere else.

Back home we watched Father Brown and Midsummer Murders on PBS. Death in Paradise had been moved ahead of Father Brown and Broadchurch, which we had already seen, was put in the 10 PM time slot. It was fabulous (another great Nicola Walker role), but we had no desire to see it a second time. We might have streamed something else instead, but I no longer recall what we did.

SUNDAY 16 October

Today was our grand-daughter Sadie’s family birthday party and brunch. She turned 4-years-old this past Thursday, and it was the first time we were able to see her, and big sister Madeline, (and son, Brendan and daughter-in-law Shawna) in person since we got home. Our daughter (Meghan) and son-in-law (Chris) were there, along with Shawna’s brother, Rob, and his family (Becky, Jack, and Juniper). It was nice to see everyone, the food was wonderful, and the kids made sure it was an energy-filled gathering.

On the drive home (Linda was driving) I texted Phil at Precision Grading, to let him know we were home. Phil has done all of our driveway and septic tank work since we bought the house, and installed a French Drain in the west portion of our property that works really well. But he is also the sub-contractor for the excavating, grading, and driveway work on the accessory building. We are on his future project list to replace the drain in the valley behind the house with a proper French Drain, so I needed to check on that as much as anything else.

At home, I went ahead and put the stinger for the Propride 3P Hitch into the receiver of the F-150 and lined it up with the hitch on the Airstream. Linda then came out and assisted with the actual hitching up process, following the procedure we had now used for almost four months. With the trailer secured to the truck, we removed and stowed the chocks and the tongue jack stand, and the combo was ready to go in the morning. I was going to finally need to use the Lot Bar, which we bought at the same time as the hitch in October 2019, so I made sure I had the necessary tools in the truck to install it once I got to the Airstream dealer tomorrow.

For dinner, Linda prepared home-made Raman from scratch (except for the noodles, of course). It was amazing (naturally), and I suggested it be added to some regular menu rotation for the coming winter months.

Sunday evening is one of our two PBS nights, featuring Masterpiece Theater. Tonight, was the first episode of the new season of Miss Scarlet and the Duke, followed by the premier of the Magpie Murders and then the US premier of Annika, staring Nicola Walker, whose work we have come to really enjoy and respect.

Tomorrow would be an early/busy day for both of us, so I set an alarm on my phone for 7 AM before turning in for the night.

MONDAY 17 October

I took today as the final day of our post trip tasks, as well as the resumption of some of our “at home” routines. My me that meant taking the travel trailer to Woodland Airstream in Grand Rapids, Michigan for the scheduled appointment to take care of our list of service items before the factory warranty expired on November 8, 2022. For Linda, that meant the first trip (of probably many) to Ann Arbor to provide child care for one or both of the younger grand-daughters while their parents worked. Today, that meant watching (playing with) Sadie, as her Montessori pre-school was closed today. She also had to hang around long enough to also spend time with Madeline after she got home from school while dad took Sadie to her ballet class.

I was scheduled to arrive at Woodland Airstream between 10 and 11 AM, and Erich (the service manager) had me on his calendar for around 10:30 AM to go over the repair list. I pulled out of the driveway at 8:15 AM for the approximately 1-hour and 45-minute drive to the northeast side of Grand Rapids, Michigan. There was a light mist as I pulled out, and I drove in and out of rain of varying intensity for the entire trip. I missed the morning rush hour traffic in and around the Lansing, Michigan area, and the trip went smoothly even with occasional construction zones.

I arrived right around 10 AM to a very light-to-intermittent rain, and parked the truck-trailer combo in a convenient spot that was not blocking traffic or parked vehicles. I checked in with Joyce, the service writer, and then checked in with Erich to see if they had chocks and blocks I could use to secure the trailer while I unhooked it. (I did not want to leave my personal chocks or jack stand, if possible.)

It was probably 10:30, or a bit later, by the time I had the truck unhooked and the Lot Bar installed. The Lot Bar is an accessory for the Propride 3P Hitch that allows the trailer to be moved around (at low speed) by a tow vehicle with a conventional trailer ball, such as on an RV dealer’s parking lot (thus the name of the device). Woodland Airstream has several of these devices, but they now charge $50 to install and uninstall them. Which is fair, as it involves some amount of time of their labor to do this if the customer doesn’t take care of it themselves. I didn’t mind doing it, even in the very light rain, as I have had this accessory since we bought the hitch, and had yet to use it. I knew exactly how it had to be installed, but had never actually done it. It was very easy. We never leave home without. In the event that we had to have unexpected repairs attended to while traveling, it is highly unlikely that most RV service facilities would have one.

Erich met with me around 10:45 AM and I walked him through a few of the items on our list that I thought would make more sense if I could just have him look at something while I pointed to the problem area. He was very attentive and, in spite of always being very busy, took the time and gave me his undivided attention. I then met with Joyce to go over the paperwork, sign it, and give her the keys. The estimated time to turn the trailer around was 3 to 4 weeks, but I told her we had no plans to use it again until spring, and it was fine with me if they took the time they needed to address everything correctly. Most of the items were already identified as warranty, but I anticipate there will be things we have to pay for, beyond the winterization. At a minimum, I want to get a couple of spare “sail switches” for the propane furnace and a spare fresh-water pump to carry as spare parts.

I had hoped to chat with Steve, our salesman, but he was tied up with a customer. I was standing near the front door, waiting to see if Steve was going to have a break, but perhaps looking a bit lost, when a gentleman standing there asked if he could help me in any way. Long story short, it was John, the CEO of Woodland Airstream, and the GM of the Grand Rapids location. We had a really nice chat, but since he asked, I shared my concerns about the bulge in the floor. He was confident they would be able to take care of it. I made sure he knew how pleased we were with all of the employees we have interacted with, starting with our very first contact with Steve in August 2019.

Woodland Airstream recently opened a location in Indianapolis, Indiana and John said it was doing very well. I also learned that they are about to break ground on a location in Clarkston, Michigan (much closer to our house) that will allow them to conveniently serve the whole southeast Michigan market, and possibly take in northwest Ohio.

While I am not completely happy with Airstream at the moment, as I think there are way too many items on our list for a 3-year-old trailer with no more than 10,000 miles on it, Woodland Airstream has been an absolutely top-notch, first-class group of people to deal with. Woodland Airstream is an Airstream exclusive dealership, as a result of which they have a great relationship with Airstream and their customers ultimately benefit from that.

It was 11:45 AM by the time I was done at the dealership. I texted Linda that I was about to head for home, but then decided to drive the short distance in the opposite direction on Plainfield Avenue NE to Anna’s House. So, I texted my change in plans. Anna’s House is local chain of restaurants that is well known for their breakfast offerings, including vegan ones. I was in the mood for lunch, however, and ordered their vegan hamburger with French fries. I should have ordered breakfast, as the burger was very disappointing. I texted Linda again when I was ready to leave the restaurant, and again when I got home around 3 PM. It’s been a long-standing practice of ours, ever since we finally had cell phones with text messaging, to let each other know when we are on the road and have reached our destinations.

Back at the house, there were trucks and a trailer down by the barn, so I figured the insulation crew was there, and walked down there to check on things. There will be more details on that in the separate accessory building project update post.

Phil (Precision Grading) called me around dinner time and we had a nice, long chat. We don’t talk too often, as Phil is very busy and works long hours, but we always have a great conversation when the opportunity presents itself.

For dinner, Linda made sandwiches of vegan deli slices and cheese with lettuce and vegan mayo on toast. We had a few Fritos and orange slices on the side.

Monday is one of our two CBS nights, so we watched our usual programs and then went to bed.

…