NOTE: This post contains two (2) photos with captions, both taken by me (Bruce) with a Google Pixel 6 Pro.

FRIDAY 09 August 2024 — Another look at refinishing our hardwood floors; more electrical work and deep-cleaning

Dan, from Functional Floors in Brighton, stopped by this morning to look at our floor refinishing project. He was the company’s Senior Estimator and was on site for about 90 minutes. He was obviously experienced and knowledgeable, and we had a good discussion, not all of it about flooring. Like Michael’s visit yesterday, some additional considerations were raised and options offered. We were very comfortable with Dan, and he e-mailed the quote that afternoon. But we also liked the fact that yesterday we were talking to the owner of a company. Choices require decisions and (rational) decisions require criteria.

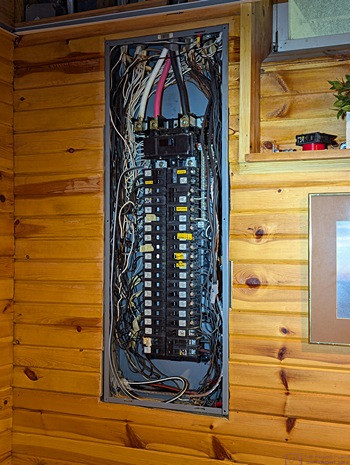

Our main electrical distribution panel with the cover removed. It’s a Square D box with 40 spaces for circuit breakers, not including the large 240VAC/200A main breaker/disconnect at the top. Some of the circuit breakers are “piggyback” devices, powering two circuits in the space of a normal single breaker, so there are more than 40 circuits originating from this box.. I am not a huge fan of piggyback circuit breakers but, in any older home which has undergone modifications to the original wiring system, they are sometimes a necessity.

When Dan left, we got back to our on-going projects; Linda with the deep-cleaning, and me with the electrical work. Having decided on an approach, I paid a visit to the barn to rummage through the storeroom and see what materials and devices I already had in stock. I have quite of bit of stuff left over from various projects, most recently the wiring of the barn, but I did not have most of what I needed for this project. I gathered up various electrical tools that I would need, put them in the truck, and then headed to Lowe’s to get wire, conduit, conduit clamps, the outlet box, GFCI outlets, and cover plates. (We had several outlet boxes around the house that did not have cover plates, and it was well past time to get some and install them.) The most economical way to get the wire was a 100-foot roll of 12-2+G NM-B (Romex) cable. It came in yellow, so it would stand out amongst the existing wiring, which is mostly white. I would make several more trips to the barn over the next days for additional tools as the need arose.

A view of part of our recreation room looking east from near the main electrical distribution panel. Suspended ceiling tiles have been moved to provide access to the floor joists so we can route the new 12-2+G NM-B cable for the new clothes dryer circuit/receptacle.

Back home, I moved some of the 2’ x 4’ acoustic ceiling panels so I could examine the floor joists in the ceiling to scout out a route for the new cable. It looked like there were existing holes in some of the joists that I could use, even though they already had one or more cables going through them. I figured the fewer holes I had to drill the better.

…