Gary Hatt purchased Bus Conversion Magazine in 2012 and published his first issue in October of that year. Starting with the February 2013 issue, Bruce has been writing articles for BCM on a fairly regular basis. As of the June 2020 issue, he has had 58 articles published in 49 separate issues. Those articles have contained over 150,000 words and approximately 1,500 images (photographs or graphics), with most of the photographs taken by him. Most of these articles have been about technical projects on our bus, but have also included “featured bus articles,” projects on other people’s buses, rallies, places to visit, and things to do.

BCM is THE unique source of information for owners of converted buses and motorcoaches, especially those doing their own conversions or redoing/maintaining a commercial conversion. All issues since 2008 are available online to active subscribers and BCM has an ongoing project to scan older (non-digital) issues and make them available in the archive.

If this looks like a magazine you would enjoy reading every month, you can also subscribe here using this link.

First time subscribers can get a 50% discount on 1-year subscription. Use Coupn Code “fay50off”.

Bruce’s articles have appeared in the following issues (in reverse chronological order). The [Nnn] is the cumulative issue count (not the issue number) and the [Ann] is the cumulative article count. The cover of each issue appears along with the article title(s) and description(s).

June 2020 – [N49] – Boondocers Welcome – A Hosts’ Perspective [A58] The Boondockers Welcome program is a web-based, membership service that allows guest members to arrange to stay overnight in their RV on the private property of host members for free or for a small donation to cover electricity (if used). We have been both host and guest members almost from the beginning of the program, but most of our experience with the program has been as a host. In this article Bruce describes the program from that perspective.

June 2020 – [N49] – Boondocers Welcome – A Hosts’ Perspective [A58] The Boondockers Welcome program is a web-based, membership service that allows guest members to arrange to stay overnight in their RV on the private property of host members for free or for a small donation to cover electricity (if used). We have been both host and guest members almost from the beginning of the program, but most of our experience with the program has been as a host. In this article Bruce describes the program from that perspective.

November 2018 – [N48] – H3-40 Air Disc Brake Failure & Repair: Part 3 of 3 [A57] In the third and final part of this series, Bruce describes the work that was undertaken on the other three air disc brakes as a preventative measure. This included replacing the calipers, pads, rotors, and slack adjusters.

November 2018 – [N48] – H3-40 Air Disc Brake Failure & Repair: Part 3 of 3 [A57] In the third and final part of this series, Bruce describes the work that was undertaken on the other three air disc brakes as a preventative measure. This included replacing the calipers, pads, rotors, and slack adjusters.

October 2018 – [N47] – H3-40 Air Disc Brake Failure & Repair: Part 2 of 3 [A56] In the second of three articles, Bruce describes the process of locating a service facility in Orlando, Florida to work on the failed brake. Because the tag axle could be lifted on an H3-40, we were able to drive the bus to the facility on six tires and avoid being towed. The facility did not normally work on buses, but was able to start work the morning after we arrived and had has back on the road in just over 48 hours.

September 2018 – [N46] – H3-40 Air Disc Brake Failure & Repair: Part 1 of 3 [A55] In this first of three articles Bruce describes the circumstances leading up to a failure of one of the ABD-1590 air disc brakes on the motorcoach. These brakes are used on the steer axle and the tag axle and it was the driver/street side tag axle brake that locked up, overheated, and almost caught on fire. He discuss the design of these brakes and the value of having a tire pressure and temperature monitoring system (TPTMS) and using it whever a rig is in motion.

September 2018 – [N46] – H3-40 Air Disc Brake Failure & Repair: Part 1 of 3 [A55] In this first of three articles Bruce describes the circumstances leading up to a failure of one of the ABD-1590 air disc brakes on the motorcoach. These brakes are used on the steer axle and the tag axle and it was the driver/street side tag axle brake that locked up, overheated, and almost caught on fire. He discuss the design of these brakes and the value of having a tire pressure and temperature monitoring system (TPTMS) and using it whever a rig is in motion.

July 2018 – [N45] – H3-40 Entry Door Latch-Lock Repair [A54] The entry door on early 1990’s Prevost H3-40 conversion shells is a slightly complicated mechanism. The overall design includes a deadbolt, a keyed latch-lock pin with interior and exterior handles, upper and lower latches, as well as an electric lock/unlock actuator and an (Ford) keypad and internal switches. Mechanically, all of this is interconnected. The tumbler in the key lock and some of the moving parts had worn and/or become misaligned to where the door could no longer be locked or unlocked/opened reliable, either from the inside or the outside of the bus. In this article Bruce reverse engineers the mechanism to diagnose the problems and fixes them, including replacing the lock and getting knew keys made.

July 2018 – [N45] – H3-40 Entry Door Latch-Lock Repair [A54] The entry door on early 1990’s Prevost H3-40 conversion shells is a slightly complicated mechanism. The overall design includes a deadbolt, a keyed latch-lock pin with interior and exterior handles, upper and lower latches, as well as an electric lock/unlock actuator and an (Ford) keypad and internal switches. Mechanically, all of this is interconnected. The tumbler in the key lock and some of the moving parts had worn and/or become misaligned to where the door could no longer be locked or unlocked/opened reliable, either from the inside or the outside of the bus. In this article Bruce reverse engineers the mechanism to diagnose the problems and fixes them, including replacing the lock and getting knew keys made.

June 2018 – [N44] – H3-40 Interior Remodel )Part 12 of 12): Trying to Wrap it Up [A53] Bruce committed to do a series of 12 articles on the interior remodel, to run in 12 consecutive issues. He hoped to have all of the major loose ends tied up in time for the final installment, but several things interfered with that goal, including a major in-frame rebuild of the Detroit Diesel 8V92TA and a subsequent shop accident interfered. Still, this is the final article in the series, as promised. He describes some of the remaining tasks and reflects on the work described over these 12 articles, which took three (3) year to accomplish, starting in May 2015.

June 2018 – [N44] – H3-40 Interior Remodel )Part 12 of 12): Trying to Wrap it Up [A53] Bruce committed to do a series of 12 articles on the interior remodel, to run in 12 consecutive issues. He hoped to have all of the major loose ends tied up in time for the final installment, but several things interfered with that goal, including a major in-frame rebuild of the Detroit Diesel 8V92TA and a subsequent shop accident interfered. Still, this is the final article in the series, as promised. He describes some of the remaining tasks and reflects on the work described over these 12 articles, which took three (3) year to accomplish, starting in May 2015.

May 2018 – [N43] – H3-40 Interior Remodel (Part 11 of 12): A Custom Built-in Storage Storage Sofa that Sleeps One — Assembly and Installation [A52] In this article Bruce describes the assembly and installation of the custom built-in storage sofa. The design, fabrication, assembly, and installation had to accommodate deliver and return air ducts for the OTA HVAC system, as well as pass-through wiring and power wiring for internal lights. The seat board / storage lid had to be widened from the original design. We did not want to have the seat cushions remade so we ordered a filler bolster covered in the same fabric.

May 2018 – [N43] – H3-40 Interior Remodel (Part 11 of 12): A Custom Built-in Storage Storage Sofa that Sleeps One — Assembly and Installation [A52] In this article Bruce describes the assembly and installation of the custom built-in storage sofa. The design, fabrication, assembly, and installation had to accommodate deliver and return air ducts for the OTA HVAC system, as well as pass-through wiring and power wiring for internal lights. The seat board / storage lid had to be widened from the original design. We did not want to have the seat cushions remade so we ordered a filler bolster covered in the same fabric.

April 2018 – [N42] – H3-40 Interior Remodel (Part 10 of 12): A Custom Built-in Storage Sofa that Sleeps One — Planning, Design, & Fabrication [A51] In this article Bruce describes the planning, design, and fabrication of a custom built-in sofa. The sofa features a fold-up seat to allow access to storage space underneath. A custom sofa was required as it needed to to tie into the OTR HVAC system for both air delivery and return.

April 2018 – [N42] – H3-40 Interior Remodel (Part 10 of 12): A Custom Built-in Storage Sofa that Sleeps One — Planning, Design, & Fabrication [A51] In this article Bruce describes the planning, design, and fabrication of a custom built-in sofa. The sofa features a fold-up seat to allow access to storage space underneath. A custom sofa was required as it needed to to tie into the OTR HVAC system for both air delivery and return.

March 2018 – [N41] – H3-40 Interior Remodel (Part 9 of 12): A Custom Built-in Desk — Assembly & Installation [A49] In this article Bruce describes the assembly and installation of the custom desk. The design and fabrication was modular, allowing the pieces to be transported from Jarel Beatty’s workshop in Logansport, Indiana back to our home in Michigan where the interior remodeling work was being done. A major assembly step was reconfiguring the OTR HVAC ducts and the fan-coil heat exchangers and coolant lines for the Aqua-Hot hydronic heating system. The fan-coil units had to be installed in the base pedestals of the two desk boxes before everything was installed in the coach. The desk was capped with a Corian surface that matched the existing kitchen counter, allowing the desk to double as a kitchen work surface. Butch & Fonda Williams’ MCI MC-9 Solar System: Powered Up for Extended Off-Grid Living (with Butch Williams) [A50] In this article Bruce describes how Butch and Fonda upgraded the house electrical system of their 1987 MCI MC-9 NJT bus conversion, with some assistance from Bruce. The article details how the four solar panels on the roof were replaced with larger ones totaling over 1,100 VA. It also describes the installation and wiring of the electrical bay, which includes eight Full-River L-16 AGM batteries, a Magnum Dimensions 4024 pure sine wave inverter/charger, a Magnum Dimensions MPPT Solar Charge Controller, and numerous other components.

March 2018 – [N41] – H3-40 Interior Remodel (Part 9 of 12): A Custom Built-in Desk — Assembly & Installation [A49] In this article Bruce describes the assembly and installation of the custom desk. The design and fabrication was modular, allowing the pieces to be transported from Jarel Beatty’s workshop in Logansport, Indiana back to our home in Michigan where the interior remodeling work was being done. A major assembly step was reconfiguring the OTR HVAC ducts and the fan-coil heat exchangers and coolant lines for the Aqua-Hot hydronic heating system. The fan-coil units had to be installed in the base pedestals of the two desk boxes before everything was installed in the coach. The desk was capped with a Corian surface that matched the existing kitchen counter, allowing the desk to double as a kitchen work surface. Butch & Fonda Williams’ MCI MC-9 Solar System: Powered Up for Extended Off-Grid Living (with Butch Williams) [A50] In this article Bruce describes how Butch and Fonda upgraded the house electrical system of their 1987 MCI MC-9 NJT bus conversion, with some assistance from Bruce. The article details how the four solar panels on the roof were replaced with larger ones totaling over 1,100 VA. It also describes the installation and wiring of the electrical bay, which includes eight Full-River L-16 AGM batteries, a Magnum Dimensions 4024 pure sine wave inverter/charger, a Magnum Dimensions MPPT Solar Charge Controller, and numerous other components.

February 2018 – [N40] – H3-40 Interior Remodel (Part 8 of 12): A Custom Built-in Desk — Planning, Design, & Fabrication [A48] In this article Bruce describes the planning and design of a custom desk to go in place of the original dinette seating and table. The desk had to meet several requirements, including a file drawer and space for a laser printer. It also had to accommodate the unique aspects of the bus and the existing conversion, especially the OT HVAC system and the Aqua-Hot hydronic heating system. Also discussed is the fabrication of all of the desk pieces by Jarel Beatty of Logansport, Indiana.

February 2018 – [N40] – H3-40 Interior Remodel (Part 8 of 12): A Custom Built-in Desk — Planning, Design, & Fabrication [A48] In this article Bruce describes the planning and design of a custom desk to go in place of the original dinette seating and table. The desk had to meet several requirements, including a file drawer and space for a laser printer. It also had to accommodate the unique aspects of the bus and the existing conversion, especially the OT HVAC system and the Aqua-Hot hydronic heating system. Also discussed is the fabrication of all of the desk pieces by Jarel Beatty of Logansport, Indiana.

January 2018 – [N39] – Adding a Tachometer to an MC-9 with a DD6V92TA DDEC I and HT-740 ATEC (with Butch Williams) [A46]; In this article Bruce describes how he and Butch installed and calibrated an ISSPRO R85215 tachometer in Butch’s 1987 MCI MC-9 NJT bus conversion while spending the winter of 2014-15 in Quartzsite, Arizona. When delivered to New Jersey Transit the bus did not include a tachometer. The R85215 got its signal from the ‘R’ terminal on the alternator and was designed to work with either 12 or 24 VDC systems. It was also adjustable, within limits, which allowed Butch to use a phototachometer to measure the RPM of the engine at low and high idle and adjust the gauge to match. H3-40 Interior Remodel (Part 7 of 12): A Custom Pull-Out Pantry [A47] In this installment Bruce describes the design, fabrication, and installation of a custom slide-out pantry, one of three custom woodworking sub-projects that were part of the remodeling project. In a previous installment he described how we removed the old side-by-side refrigerator and replaced it with a new, slightly smaller, top-and-bottom unit. The new fridge was not as wide, leaving space to its left for the pull-out pantry. Bruce did the design using dimensioned scale drawings on grid paper. Jarel Beatty, a cabinetmaker in Logansport, Indiana fabricated the unit. (Jarel is a long-time friend of Bruce’s frequent co-author, Butch Williams). It took both of us to do the actual installation.

December 2017 – [N38] – H3-40 Interior Remodel (Part 6 of 12): Chairs and Window Treatments [A45]; In this installment Bruce describes the selection and installation of new Flexsteel captain’s chairs and MCD window treatments from Josh Leach of Coach Supply Direct in Edwardsburg, Michigan.

December 2017 – [N38] – H3-40 Interior Remodel (Part 6 of 12): Chairs and Window Treatments [A45]; In this installment Bruce describes the selection and installation of new Flexsteel captain’s chairs and MCD window treatments from Josh Leach of Coach Supply Direct in Edwardsburg, Michigan.

November 2017 – [N37] – H3-40 Interior Remodel (Part 5 of 12): Wallpaper and Cockpit Floor [A44]; One of our major design goals was to have the same flooring from the entry stairs all the way to the end of the bedroom in the rear of the bus. When we got to the cockpit, however, we had to put the tile work on hold until we took care of a couple of other things. We never used the air-actuated stepwell cover and decided to remove it. We also discovered serious water damage to the plywood subfloor under the driver and navigator seats. These two things melded into a single, major sub-project. While this repair work was underway, Linda worked on removing old wallpaper and preparing the walls for the new wallcovering.

November 2017 – [N37] – H3-40 Interior Remodel (Part 5 of 12): Wallpaper and Cockpit Floor [A44]; One of our major design goals was to have the same flooring from the entry stairs all the way to the end of the bedroom in the rear of the bus. When we got to the cockpit, however, we had to put the tile work on hold until we took care of a couple of other things. We never used the air-actuated stepwell cover and decided to remove it. We also discovered serious water damage to the plywood subfloor under the driver and navigator seats. These two things melded into a single, major sub-project. While this repair work was underway, Linda worked on removing old wallpaper and preparing the walls for the new wallcovering.

October 2017 – [N36] – Raising the Bar: A Unique Destination in the Desert [A42]; During our 2015 winter in Quartzsite, Arizona we went to The Desert Bar (Nellie E. Saloon). This unique destination is located at an old mining site (The Nellie E. Mine) in the Buckskin Mountains northeast of Parker, Arizona. It is off-the-grid and out-of-this-world. H3-40 Interior Remodel (Part 4 of 12): Floor Tile. [ A43] This installment describes the selection and installation of the Armstrong ALTERNA Groutable Luxury Tile, which had to precede all of the other remodeling.

October 2017 – [N36] – Raising the Bar: A Unique Destination in the Desert [A42]; During our 2015 winter in Quartzsite, Arizona we went to The Desert Bar (Nellie E. Saloon). This unique destination is located at an old mining site (The Nellie E. Mine) in the Buckskin Mountains northeast of Parker, Arizona. It is off-the-grid and out-of-this-world. H3-40 Interior Remodel (Part 4 of 12): Floor Tile. [ A43] This installment describes the selection and installation of the Armstrong ALTERNA Groutable Luxury Tile, which had to precede all of the other remodeling.

September 2017 – [N35] – H3-40 Engine Radiator Fan Drive Repair: Part 2 of 2 (with Butch Williams) [A40]; Besides the shaft seal leaks on the angle drive gearboxes, as described in Part 1 of this 2-part article, our friend’s pillow block had a badly worn self-aligning bearing that was on the verge of failure. When Butch removed the driveshaft from the pillow block he discovered that the shaft was badly damaged. Our friend was able to source a replacement bearing, but the driveshaft was not available from Prevost. Butch was able to make a new shaft. H3-40 Interior Remodel (Part 3 of 12): Reconstruction Begins … and we get a new refrigerator! [A41] As the title suggests, part of this article has to do with removing and replacing our residential refrigerator. The rest of the article has to do with final preparations for installing the new vinyl floor tile.

September 2017 – [N35] – H3-40 Engine Radiator Fan Drive Repair: Part 2 of 2 (with Butch Williams) [A40]; Besides the shaft seal leaks on the angle drive gearboxes, as described in Part 1 of this 2-part article, our friend’s pillow block had a badly worn self-aligning bearing that was on the verge of failure. When Butch removed the driveshaft from the pillow block he discovered that the shaft was badly damaged. Our friend was able to source a replacement bearing, but the driveshaft was not available from Prevost. Butch was able to make a new shaft. H3-40 Interior Remodel (Part 3 of 12): Reconstruction Begins … and we get a new refrigerator! [A41] As the title suggests, part of this article has to do with removing and replacing our residential refrigerator. The rest of the article has to do with final preparations for installing the new vinyl floor tile.

August 2017 – [N34] – Repairing the Angle-Drive Gearbox and Pillow Block for the Engine Radiator Fan-Drive Assembly in a Prevost H3-40: Part 1 of 2 (with Butch Williams) [A38]; The Prevost H3-40/VIP has a driver side mounted engine radiator so the radiator fan cannot be mounted on the “front” (rear-facing end) of the engine. Instead, the fan is mounted to the output shaft of a right-angle gearbox. The input to the gearbox is from a driveshaft supported in a pillow block. A pulley on the other end of the driveshaft is driven by a belt off of a pulley on the engine crankshaft. The right angle gearbox was oil-filled, but was leaking around the shaft seals, and a friend’s H3-40 was showing the same problem. Removing and replacing the assemblies was specific to the H3-40 model from the early 1990’s, but the repair was similar to the T-drive described in the July 2017 MC-9 radiator blower article. H3-40 Interior Remodel (Part 2 of 12): Deconstruction. [A39] With the new interior planned the next step was to remove the existing furniture from the front half of the coach, the toilet, and all of the flooring, which was a mix of vinyl tile, carpet, and ceramic tile. We also had to remove wallpaper and some of the vertical strip mirrors.

August 2017 – [N34] – Repairing the Angle-Drive Gearbox and Pillow Block for the Engine Radiator Fan-Drive Assembly in a Prevost H3-40: Part 1 of 2 (with Butch Williams) [A38]; The Prevost H3-40/VIP has a driver side mounted engine radiator so the radiator fan cannot be mounted on the “front” (rear-facing end) of the engine. Instead, the fan is mounted to the output shaft of a right-angle gearbox. The input to the gearbox is from a driveshaft supported in a pillow block. A pulley on the other end of the driveshaft is driven by a belt off of a pulley on the engine crankshaft. The right angle gearbox was oil-filled, but was leaking around the shaft seals, and a friend’s H3-40 was showing the same problem. Removing and replacing the assemblies was specific to the H3-40 model from the early 1990’s, but the repair was similar to the T-drive described in the July 2017 MC-9 radiator blower article. H3-40 Interior Remodel (Part 2 of 12): Deconstruction. [A39] With the new interior planned the next step was to remove the existing furniture from the front half of the coach, the toilet, and all of the flooring, which was a mix of vinyl tile, carpet, and ceramic tile. We also had to remove wallpaper and some of the vertical strip mirrors.

July 2017 – [N33] – MCI MC-9 Engine Radiator Blower Repair (with Butch Williams) [A36]; Many generations of Motor Coach Industries (MCI) buses, including the MC-9, used a dual engine radiator design. The radiators were mounted above the engine compartment facing the left and right sides of the coach. A pair of squirrel cage blowers were mounted behind the radiators with a T-drive (right angle gear box) in-between them. The T-drive was driven by a belt running vertically off of the engine. The T-drive was oil filled. When Butch discovered that his T-drive did not have very much oil in it, he removed it, disassembled it, cleaned it up, and replaced the shaft seals. He also did some sheet metal repair on the blower housings. Bruce was there to help reinstall everything. H3-40 Interior Remodel (Part 1 of 12): Planning the Project. [A37] Our coach was built in August 1990 and the original conversion was completed in October 1991, so by October of 2014 the interior was at least 24 years old and we had owned it for 5-1/2 years. That was long enough to know what we liked, and what we didn’t like, about the layout and materials. While wintering in the southwest U. S., we decided that 2015 would be the year to undertake a major remodeling of the interior. Step one was planning the project.

July 2017 – [N33] – MCI MC-9 Engine Radiator Blower Repair (with Butch Williams) [A36]; Many generations of Motor Coach Industries (MCI) buses, including the MC-9, used a dual engine radiator design. The radiators were mounted above the engine compartment facing the left and right sides of the coach. A pair of squirrel cage blowers were mounted behind the radiators with a T-drive (right angle gear box) in-between them. The T-drive was driven by a belt running vertically off of the engine. The T-drive was oil filled. When Butch discovered that his T-drive did not have very much oil in it, he removed it, disassembled it, cleaned it up, and replaced the shaft seals. He also did some sheet metal repair on the blower housings. Bruce was there to help reinstall everything. H3-40 Interior Remodel (Part 1 of 12): Planning the Project. [A37] Our coach was built in August 1990 and the original conversion was completed in October 1991, so by October of 2014 the interior was at least 24 years old and we had owned it for 5-1/2 years. That was long enough to know what we liked, and what we didn’t like, about the layout and materials. While wintering in the southwest U. S., we decided that 2015 would be the year to undertake a major remodeling of the interior. Step one was planning the project.

June 2017 – [N32] – A Simple Door Latch for a Residential Refrigerator (with Butch Williams) [A35]; We began a major interior remodeling of our coach in the spring of 2015. As part of that project we replaced the old side-by-side residential refrigerator with a new top-and-bottom unit. With the side-by-by side we were able to secure the doors with a large spring clamp at the top end of the two handles, which met near the vertical centerline of the unit. For the new refrigerator we needed a different approach. We had seen a turn-latch in a display motorhome that looked like a simple solution. Butch Williams was able to fabricate a similar device that took advantage of the three screw holes that were already in the case between the doors at the right edge. The doors came hinged on the left, which is where we needed them, but the extra holes were there to allow the doors to be hinged on the right if needed.

June 2017 – [N32] – A Simple Door Latch for a Residential Refrigerator (with Butch Williams) [A35]; We began a major interior remodeling of our coach in the spring of 2015. As part of that project we replaced the old side-by-side residential refrigerator with a new top-and-bottom unit. With the side-by-by side we were able to secure the doors with a large spring clamp at the top end of the two handles, which met near the vertical centerline of the unit. For the new refrigerator we needed a different approach. We had seen a turn-latch in a display motorhome that looked like a simple solution. Butch Williams was able to fabricate a similar device that took advantage of the three screw holes that were already in the case between the doors at the right edge. The doors came hinged on the left, which is where we needed them, but the extra holes were there to allow the doors to be hinged on the right if needed.

May 2017 – [N31] – Repairing the Pneumatic Belt-tensioning System in a Prevost H3-40 (with Butch Williams) [A34]; Our coach uses pneumatic cylinders to tension the drive belts for the engine radiator and the OTR A/C compressor. The cylinders, which have internal springs, also use air to counter the spring pressure on the pistons, releasing the pressure from the belts so they can be easily removed. The wiper seals on the pistons and the shaft seals were leaking. We were able to source replacement parts so we disconnected and removed both cylinders and Bruce took them to Butch Williams shop in Indiana. Butch and Bruce were able to disassemble them, clean them up, replace the seals, and reassemble them. Bruce brought them back home and we re-installed them. We also replaced the cross-over valve and pressure regulator that control the air to the cylinders.

May 2017 – [N31] – Repairing the Pneumatic Belt-tensioning System in a Prevost H3-40 (with Butch Williams) [A34]; Our coach uses pneumatic cylinders to tension the drive belts for the engine radiator and the OTR A/C compressor. The cylinders, which have internal springs, also use air to counter the spring pressure on the pistons, releasing the pressure from the belts so they can be easily removed. The wiper seals on the pistons and the shaft seals were leaking. We were able to source replacement parts so we disconnected and removed both cylinders and Bruce took them to Butch Williams shop in Indiana. Butch and Bruce were able to disassemble them, clean them up, replace the seals, and reassemble them. Bruce brought them back home and we re-installed them. We also replaced the cross-over valve and pressure regulator that control the air to the cylinders.

August 2016 – [N30] – Installing the OASIS Combi Hydronic Heating System (with Butch Williams) [A33]; In the fall of 2014 Butch and Fonda Williams replaced an Aqua-Hot hydronic heating system with a new OASIS Combi unit from International Thermal Research (ITR). Bruce was on site to help with the installation, take photos, and co-author this article with Butch.

June 2016 – [N29] – Servicing the Webasto DBW2010 Burner [A32]; While we were in Quartzsite for winter 2014/15 Bruce ordered a burner service kit from Sure Marine Service (SMS). He pulled the burner assembly out of our Aqua-Hot diesel-fired hydronic heating system and serviced it. This article documents the process in words and photographs, with some lessons learned.

May 2016 – [N28] – From Arcadia and Back: Full Circle in an MCI-5C [A31]; We attended the Arcadia Rally 2016 at the end of December 2015. Bruce took lots of photographs for the article about the rally that appeared in the March 2016 issue. He also met David Aungier, who had a 1977 MCI MC-5C conversion. Dave already had a draft version of an article about his bus and the conversion process, but needed photos and assistance getting the article finished and submitted to BCM. Bruce gladly helped with both. This was the “featured bus” (cover/centerfold) article for this issue.

April 2016 – [N27] – Happy Days III — Ronnie and Diann Mewbourn’s 1969 Model 7 Eagle [A30]; Bruce first made the acquaintance of Ronnie and Diann at the Arcadia Rally 2014 (at the end of December 2013). He saw their converted Eagle at that time but did not have time to photograph it or interview them about the conversion. They were back for the Arcadia Rally 2016 (at the end of December 2015) and Bruce made a point of interviewing them and photographing their bus. This was the “featured bus” (cover/centerfold) article for this issue.

March 2016 – [N26] — Habitat For Humanity and RVing – Part 2 of 2 [A29] ~and~ Arcadia Rally 2016 [A28]; Bruce had two articles in this issue, part 2 of the HFH build article and an article on the converted bus rally held in Arcadia, Florida on December 29, 30, and 31, 2015. The rally article was the cover/centerfold article for this issue.

March 2016 – [N26] — Habitat For Humanity and RVing – Part 2 of 2 [A29] ~and~ Arcadia Rally 2016 [A28]; Bruce had two articles in this issue, part 2 of the HFH build article and an article on the converted bus rally held in Arcadia, Florida on December 29, 30, and 31, 2015. The rally article was the cover/centerfold article for this issue.

February 2016 – [N25] — Habitat For Humanity and RVing – Part 1 of 2 [A27]; In July 2013 we participated in our first building project with Habitat for Humanity. It was a two week commitment organized through the RV Care-A-Vanners desk at HFH headquarters in Americus, Georgia. It was also an all Escapees team of 18 people, many of whom came to Sheridan, Wyoming directly from the SKP Escapade rally in Gillette, Wyoming.

February 2016 – [N25] — Habitat For Humanity and RVing – Part 1 of 2 [A27]; In July 2013 we participated in our first building project with Habitat for Humanity. It was a two week commitment organized through the RV Care-A-Vanners desk at HFH headquarters in Americus, Georgia. It was also an all Escapees team of 18 people, many of whom came to Sheridan, Wyoming directly from the SKP Escapade rally in Gillette, Wyoming.

December 2015 – [N24] — Ultimate Owner Built Craftsmanship – Byron and Betty Pigg’s 1985 Model 15 Eagle [A26]; Bruce saw this bus at the FMCA Eagles International chapter rally in Quartzsite, AZ in January 2015 and was able to interview the owners and photograph their bus. This was the “featured bus” (cover/centerfold) article for this issue.

December 2015 – [N24] — Ultimate Owner Built Craftsmanship – Byron and Betty Pigg’s 1985 Model 15 Eagle [A26]; Bruce saw this bus at the FMCA Eagles International chapter rally in Quartzsite, AZ in January 2015 and was able to interview the owners and photograph their bus. This was the “featured bus” (cover/centerfold) article for this issue.

November 2015 – [N23] — Desert Fox – Larry and Carol Hall’s GM 4106 [A25]; Bruce saw this bus at the FMCA Western GM Bus chapter rally in Quartzsite, AZ in January 2015 and was able to interview the owners and photograph their bus. This was the “featured bus” (cover/centerfold) article for this issue.

November 2015 – [N23] — Desert Fox – Larry and Carol Hall’s GM 4106 [A25]; Bruce saw this bus at the FMCA Western GM Bus chapter rally in Quartzsite, AZ in January 2015 and was able to interview the owners and photograph their bus. This was the “featured bus” (cover/centerfold) article for this issue.

October 2015 – [N22] — Replacing The Speedometer [A24]; In this article Bruce describes how he removed the old non-functioning speedometer/odometer from the dashboard and replaced it with a new VDO electronic unit. One of the features of this new unit was that it could be calibrated, in several different ways. Bruce describes the method he selected and the process he used.

October 2015 – [N22] — Replacing The Speedometer [A24]; In this article Bruce describes how he removed the old non-functioning speedometer/odometer from the dashboard and replaced it with a new VDO electronic unit. One of the features of this new unit was that it could be calibrated, in several different ways. Bruce describes the method he selected and the process he used.

August/September 2015 – [N21] — Low Turbo Boost Pressure [A23] ~and~ Keep The Critters Out [A22]; That’s right, Bruce had two articles in this double issue. In Low Turbo Boost Pressure he describes the loss of adequate turbo boost while traversing the mountains of southwest Texas in December 2014 and how he and Butch found and repaired the problem. In Keep The Critters Out he reviews the RV Critter Guard product and describes the process he went through to install it.

July 2015 – [N20] — Exterior Makeover – Part 4 of 4 [A21]; In part 4 of this 4-part article Bruce describes the reassembly and upgrading of the body, the installation of new awnings, and other miscellaneous work that he accomplished while the coach was at Phoenix Paint.

July 2015 – [N20] — Exterior Makeover – Part 4 of 4 [A21]; In part 4 of this 4-part article Bruce describes the reassembly and upgrading of the body, the installation of new awnings, and other miscellaneous work that he accomplished while the coach was at Phoenix Paint.

June 2015 – [N19] — Exterior Makeover – Part 3 of 4 [A20]; In part 3 of this 4-part article Bruce describes the process we went through to replace the seals on the awning style windows. He also covers the upgrading and reassembly of the roof-mounted components.

May 2015 – [N18] — Exterior Makeover – Part 2 of 4 [A19]; In part 2 of this 4-part article Bruce describes the body repair work, paint preparation, paint design, and painting of the coach.

April 2015 – [N17] — Exterior Makeover – Part 1 of 4 [A18]; Bruce’s article on the exterior renovation of our Prevost H3-40 Royale Coach at Phoenix Paint in Edwardsburg, Michigan in 2011 and 2012. Because the work was so extensive and there were so many photographs, this article was divided into four parts. Parts 2, 3, & 4 are scheduled for the May, June, and July 2015 issues. In part 1 he describes the circumstances and decision process that led to the work described in the rest of the article, starting with the repair and re-coating of the roof.

March 2015 – [N16] — Roadside Repair – Main Engine Air-Compressor Failure [A17]; Bruce’s article on the failure of the main engine air-compressor on a friends’ bus while we were caravanning to the southwest for the winter, how the owner dealt with it on the road, and how he repaired it once we got to our wintering grounds in Quartzsite, Arizona.

February 2015 – [N15] — Quartzsite 2015 [A16]; Bruce’s article on our first visit to Quartzsite including the Eagles International and FMCA Western GM Bus rallies, the Bluebird/Wanderlodge gathering, Quartzfest, The “Big Tent” Show, Escapees Happy Hour, Joshua Tree National Park, KOFA NWR Palm Canyon, Yuma, Parker, the Desert Bar, and other places and events. (Note: There are two photos here because BCM started publishing the Digital Edition with an extended digital only Bonus Content Section. The second photo, on the right, was the first page of the BCS. It is a picture of Larry and Carol Hall’s GMC conversion and was taken by Bruce. Because Bruce’s articles tend to be long, with lots of photos, BCM split this one between the Print Edition and the DE-BCS.)

February 2015 – [N15] — Quartzsite 2015 [A16]; Bruce’s article on our first visit to Quartzsite including the Eagles International and FMCA Western GM Bus rallies, the Bluebird/Wanderlodge gathering, Quartzfest, The “Big Tent” Show, Escapees Happy Hour, Joshua Tree National Park, KOFA NWR Palm Canyon, Yuma, Parker, the Desert Bar, and other places and events. (Note: There are two photos here because BCM started publishing the Digital Edition with an extended digital only Bonus Content Section. The second photo, on the right, was the first page of the BCS. It is a picture of Larry and Carol Hall’s GMC conversion and was taken by Bruce. Because Bruce’s articles tend to be long, with lots of photos, BCM split this one between the Print Edition and the DE-BCS.)

December 2014 – [N14] — Charging The House Batteries While You Drive [A15]; Bruce’s article on the installation of a ZENA power generating system. The system consists of a 3-phase engine driven alternator, three control modules, and an AC-to-DC rectifier in the house electrical bay where the house batteries are located, plus wiring and fuses. Some of the work was done by Joe Cannarozzi and the rest was done by Bruce.

December 2014 – [N14] — Charging The House Batteries While You Drive [A15]; Bruce’s article on the installation of a ZENA power generating system. The system consists of a 3-phase engine driven alternator, three control modules, and an AC-to-DC rectifier in the house electrical bay where the house batteries are located, plus wiring and fuses. Some of the work was done by Joe Cannarozzi and the rest was done by Bruce.

October 2014 – [N13] — Spinner II Centrifugal Engine Oil Cleaner [A14]; Bruce’s article on the installation of a T. F. Hudgen’s Spinner II centrifugal bypass oil cleaner on our DD8V92TA engine. Much of the work was done by Joe Cannarozzi, the mechanic who has maintained our chassis since we bought the coach in 2009 and helped with other projects.

October 2014 – [N13] — Spinner II Centrifugal Engine Oil Cleaner [A14]; Bruce’s article on the installation of a T. F. Hudgen’s Spinner II centrifugal bypass oil cleaner on our DD8V92TA engine. Much of the work was done by Joe Cannarozzi, the mechanic who has maintained our chassis since we bought the coach in 2009 and helped with other projects.

September 2014 – [N12] — Fuel System Care During Long Term Parking [A13]; Bruce’s article on the installation of a Parker Fuel Polishing Module (FPM-50) in the supply and return fuel lines for our Aqua-Hot hydronic heating system. The FPM slowly circulates fuel from our main tank (50 gallons per 24 hours) through the Racor fuel filter / water separator that was already installed for the Aqua-Hot. The slow circulation allows the filter to more effectively and continuously remove even fine contaminants and moisture.

September 2014 – [N12] — Fuel System Care During Long Term Parking [A13]; Bruce’s article on the installation of a Parker Fuel Polishing Module (FPM-50) in the supply and return fuel lines for our Aqua-Hot hydronic heating system. The FPM slowly circulates fuel from our main tank (50 gallons per 24 hours) through the Racor fuel filter / water separator that was already installed for the Aqua-Hot. The slow circulation allows the filter to more effectively and continuously remove even fine contaminants and moisture.

August 2014 – [N11] — Window Repair: I Can See Clearly Now [A12]; We have eight awning style “Thermopane” windows in our bus and over time the seals on four of them had failed, causing them to fog and sweat internally. One even started filling up with water in a hard rain! We went to Suncoast Designers, Inc. in Hudson, Florida in early April 2014 to have them repaired and while we were there we got a tour of the factory and Bruce interviewed General Manager Jeff Heyen.

June 2014 – [N10] — Cool Cruiser: Architectural Style [A11] ~and~ Repairing The Generator Exhaust Pipe [A10]; Bruce saw this 1957 GMC PD4104 at the 2014 Arcadia Bus Rally and was able to interview owner Frank Morrison and photograph the bus for the featured bus (cover/centerfold) article in this issue. The bus was originally converted in 1986 by an architect in Midland, Michigan and the interior reflects his concern for design, materials, and craftsmanship. Bruce also had a technical article in this issue on Repairing The Generator Exhaust Pipe. This was the third of three articles on the work he did on our generator bay.

June 2014 – [N10] — Cool Cruiser: Architectural Style [A11] ~and~ Repairing The Generator Exhaust Pipe [A10]; Bruce saw this 1957 GMC PD4104 at the 2014 Arcadia Bus Rally and was able to interview owner Frank Morrison and photograph the bus for the featured bus (cover/centerfold) article in this issue. The bus was originally converted in 1986 by an architect in Midland, Michigan and the interior reflects his concern for design, materials, and craftsmanship. Bruce also had a technical article in this issue on Repairing The Generator Exhaust Pipe. This was the third of three articles on the work he did on our generator bay.

April 2014 – [N09] — The Iron Horse; Wild West Elegance [A09]; This was the cover/centerfold article and provided extensive coverage of a 1984 Model 10 Eagle converted in the style of a 19th century Pullman parlor car. Bruce saw this bus at the Arcadia rally and was able to interview the owners, Jimmy and Sadie Clay, and also photograph the bus.

February 2014 – [N08] — The Arcadia Bus Rally [A08]; This was the cover/centerfold article and provided extensive coverage of the largest bus rally currently being held in the U. S. Bruce provided hundreds of photographs of the buses, people, facilities, and community. Dave Rush of Tikvah Marketing also provided extensive photo coverage of the buses. The main article has ~40 photos and the digital edition has an additional 150+ photos. In addition to the print version, the digital edition is available in Standard Definition to e-mail and online subscribers, and in High Definition to online subscribers.

January 2014 – [N07] — The GLAMARAMA 2013 Rally [A07]; This was the cover/centerfold article and provided extensive coverage of the first area rally organized by the Great Lakes Area Motor Coach Association (GLAMA) of the Family Motor Coach Association (FMCA). We were there with our FMCA Great Lakes Converted Coaches chapter, and Bruce did a version of this article for the GLCC January newsletter, but the emphasis in this BCM article was to introduce BCM readers to what goes on at larger rallies and suggest that they give one a try if they have never attended one. In addition to the print version, the digital edition is available to e-mail and online subscribers and contains additional photos.

January 2014 – [N07] — The GLAMARAMA 2013 Rally [A07]; This was the cover/centerfold article and provided extensive coverage of the first area rally organized by the Great Lakes Area Motor Coach Association (GLAMA) of the Family Motor Coach Association (FMCA). We were there with our FMCA Great Lakes Converted Coaches chapter, and Bruce did a version of this article for the GLCC January newsletter, but the emphasis in this BCM article was to introduce BCM readers to what goes on at larger rallies and suggest that they give one a try if they have never attended one. In addition to the print version, the digital edition is available to e-mail and online subscribers and contains additional photos.

January 2014 Special Edition — The GLAMARAMA 2013 Rally; The folks at GLAMA were very pleased with the article and asked if they could distribute it as part of their area newsletter. BCM publisher Gary Hall agreed and had BCM editor Mike Sullivan produce a special edition cover with a special FMCA discount. (Note: I still consider this to be the 7th issue in which I had an article and the 7th article of mine that BCM published.)

January 2014 Special Edition — The GLAMARAMA 2013 Rally; The folks at GLAMA were very pleased with the article and asked if they could distribute it as part of their area newsletter. BCM publisher Gary Hall agreed and had BCM editor Mike Sullivan produce a special edition cover with a special FMCA discount. (Note: I still consider this to be the 7th issue in which I had an article and the 7th article of mine that BCM published.)

December 2013 – [N06] — The Auxiliary Air System [A06]; This 3-1/2 page article describes the building of a new panel to replace the existing one, the removal of the old panel, and the installation of the new one. The panel supplies/controls pressurized air to operate numerous air-powered accessories. It is tied in to the auxiliary air system of the bus and an auxiliary air compressor for use when the coach is parked and being used as a motorhome.

December 2013 – [N06] — The Auxiliary Air System [A06]; This 3-1/2 page article describes the building of a new panel to replace the existing one, the removal of the old panel, and the installation of the new one. The panel supplies/controls pressurized air to operate numerous air-powered accessories. It is tied in to the auxiliary air system of the bus and an auxiliary air compressor for use when the coach is parked and being used as a motorhome.

October 2013 – [N05] — Back To The Bricks Rally [A05]; This 10-page cover/centerfold article describes the joint mid-August rally in Clio, Michigan of the FMCA Great Lakes Converted Coaches (GLCC) chapter and the Converted Coach Owners, an independent group of converted bus owners. The article includes extensive photographs of the wide variety of converted buses that were there. The rally is held at the same time as the famous Woodward Dream Cruise in the northern Detroit suburbs and the smaller, but very nice Back To The Bricks car event held in Flint, about 10 miles from the rally site.

July 2013 – [N04] — Plumbing The Genset Air Springs [A04]; A short article on connecting the air bags that support the auxiliary powerplant together in pairs, with a Schrader valve and pressure gauge for each pair.

July 2013 – [N04] — Plumbing The Genset Air Springs [A04]; A short article on connecting the air bags that support the auxiliary powerplant together in pairs, with a Schrader valve and pressure gauge for each pair.

May 2013 – [N03] — Soundproofing The House Auxiliary Power Plant Bay [A03]; An article on removing the old, deteriorated soundproofing from the auxiliary generator bay and installing Soundown acoustical and vibration dampening material.

May 2013 – [N03] — Soundproofing The House Auxiliary Power Plant Bay [A03]; An article on removing the old, deteriorated soundproofing from the auxiliary generator bay and installing Soundown acoustical and vibration dampening material.

March 2013 – [N02] — The “All Electric” Coach [A02]; An article on redoing the house electrical system, including replacing two Heart Interface inverter/chargers with a single Magnum inverter/charger, changing the house battery bank to 24 VDC, and installing Lifeline L16 AGM batteries.

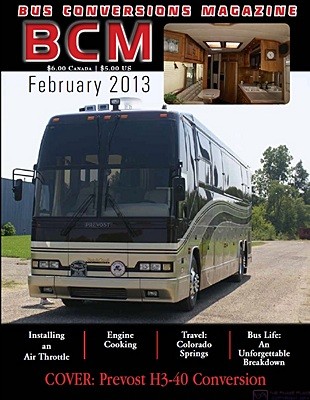

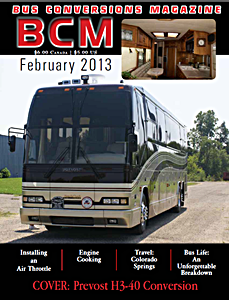

February 2013 – [N01] — Prevost H3-40 Convesion (Cover and Centerfold) [A01]; A 12-page article on the process of finding, buying, repairing, and upgrading a 17 year old Prevost H3-40 Royale Coach (Monaco) conversion. (See larger photo at beginning of this page.)

Pingback: 2013_11-16_12-06 Time Flies | The Phase Place